304 Stainless Steel Bag Filter Housing for Well Water Cooling Water and Chemical Wastewater Treatment

Product DESCRIPTION

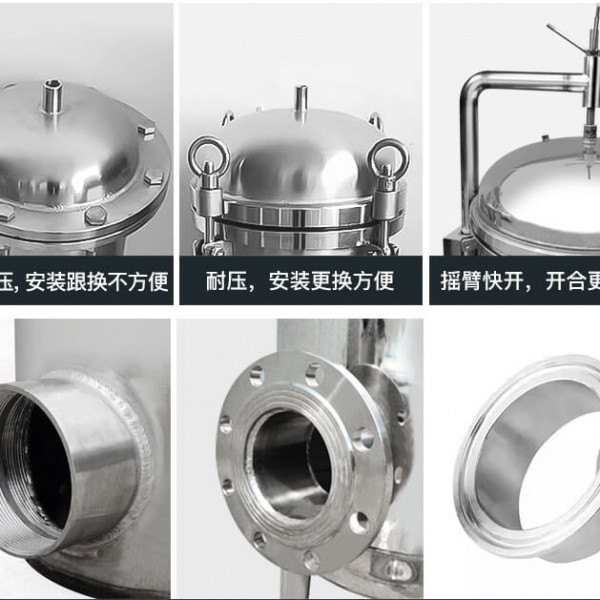

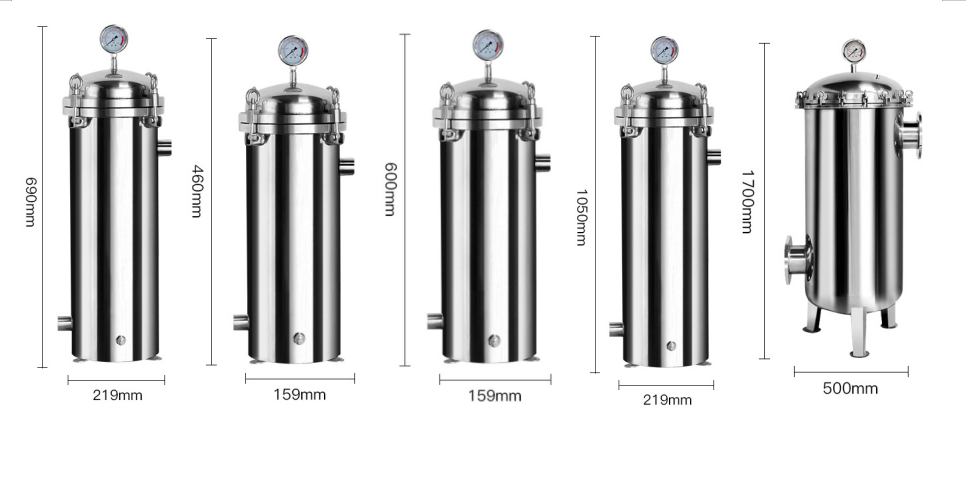

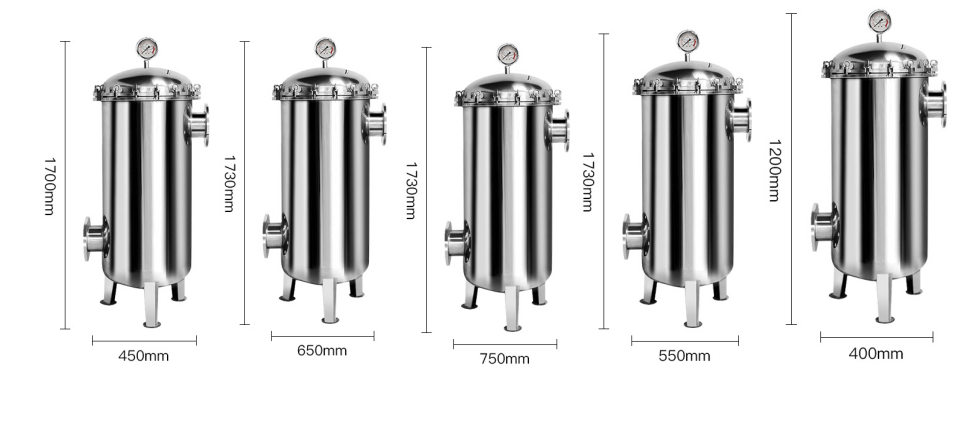

Our high-performance industrial 304 stainless steel bag filter housing is designed for efficient filtration of well water, cooling water, and chemical wastewater. This precision-engineered bag filter offers a well-constructed, tightly sealed design, ensuring strong flow capacity and easy operation. Its robust structure minimizes the risk of side leakage and boasts large flow rates and vast filter areas to guarantee precise filtration accuracy. Quick and straightforward filter bag replacement lowers operational costs, while the filter’s interior and exterior surfaces are treated with sandblasting or polishing for even, easy-to-clean finishes. The filter bag method can be configured as side-inlet side-outlet or side-inlet bottom-outlet, making this versatile filter suitable for various industrial applications.

Product Benefit

- High Efficiency: The filter’s large flow and expansive filtration area ensure thorough and efficient filtration, suitable for various industrial liquids.

- Cost-Effective Maintenance: Easy and fast replacement of filter bags reduces downtime and operational costs.

- Durable and Robust: Made from 304 stainless steel, the filter guarantees high corrosion resistance and longevity, even in harsh treatment environments.

- Maintenance Convenience: The system’s design allows for easy access and maintenance, reducing downtime and work intensity for users.

- Cleanliness and Hygiene: Treated surfaces (sandblast or polished) provide a smooth, easy-to-clean finish, maintaining hygiene and performance standards.

- Customizable Filters: A broad selection of filter bag types ensures compatibility with a wide array of filtration applications, allowing users to choose the most appropriate material for their needs.

Product Feature

- Reasonable and Robust Design

– Well-Constructed Filtration Unit: The bag filter features a rational structure with high sealing performance, ensuring minimal risk of side leakage and maximum filtration efficiency.

– Strong Flow Capacity: Designed to handle large flow rates, providing efficient filtration even in high-demand industrial settings.

– Ease of Operation: Simple design allows for easy installation, operation, and maintenance. - Versatility and Customization

– Multiple Inlet/Outlet Configurations: The filter can be set up with side-inlet side-outlet or side-inlet bottom-outlet, meeting various needs and installation requirements.

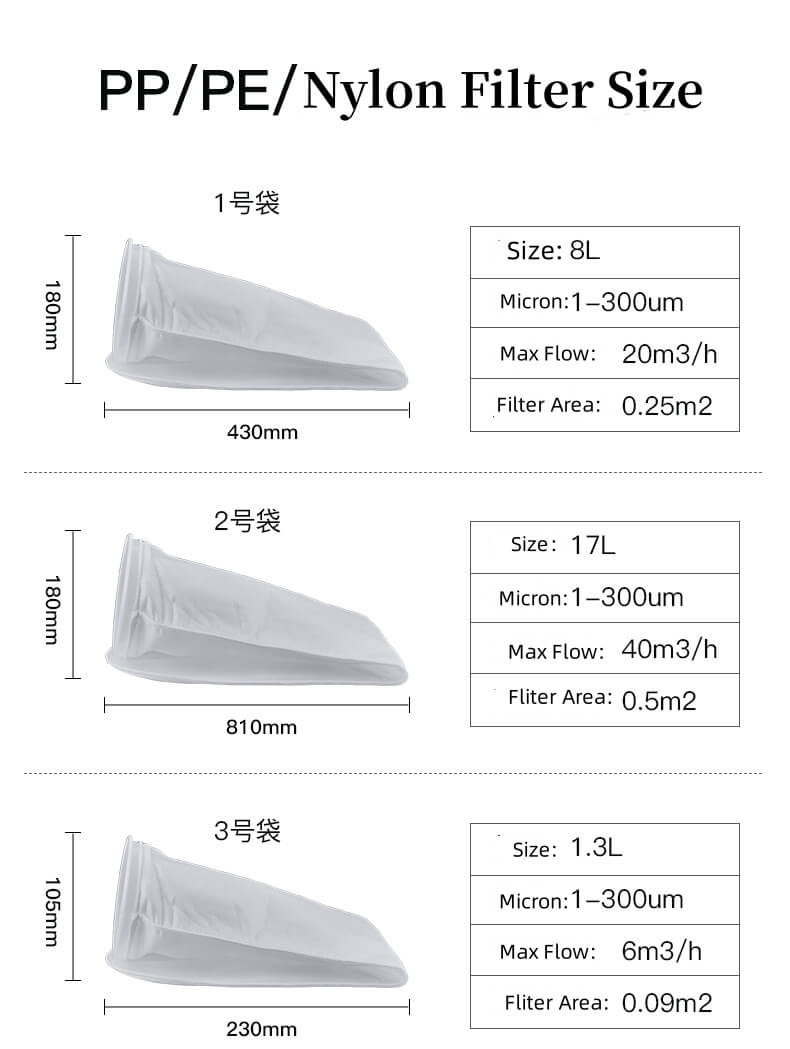

– Flexible Material Choices: A wide range of filter bag materials to suit different applications:

– PP Nonwoven Precision Filter: 0.5-200 microns, corrosion-resistant up to 80°C.

– PE Nonwoven Precision Filter: 0.5-200 microns, corrosion-resistant up to 100°C.

– Multilayer Oil Absorbent Bags: 0.5-20 microns, corrosion-resistant up to 80°C.

– PTFE Filter Bags: 0.5-200 microns, corrosion-resistant up to 180°C.

– Nylon Coarse Filter Bags: 25-1000 microns, corrosion-resistant up to 100°C, can be cleaned and reused.

– Stainless Steel Filter Bags: 25-2000 microns, corrosion-resistant up to 300°C, can be cleaned and reused.

– Multilayer Stainless Steel Composite Mesh: 1-1000 microns, corrosion-resistant up to 400°C, can be cleaned and reused. - Efficient Filtration Mechanism

– Pressurized Filtration: Liquid enters the filter under pressure, flowing into the filter bag housed within a reinforced basket to prevent rupture from overpressure.

– Precise Filtration: Liquid passes through filter bags graded for specific levels of fineness, ensuring the capture of impurities and delivering the desired quality of filtrate.

– Minimal Material Waste: The filtration process effectively captures impurities without significant material consumption.

Product APPLICATION

- This versatile industrial bag filter is suitable for numerous applications, including but not limited to:

- Well Water Filtration: Removes impurities and sediments from well water, ensuring safe and clean water for industrial processes.

- Cooling Water Systems: Ensures efficient cooling by removing particulates from circulating cooling water, maintaining system efficiency and longevity.

- Chemical and Pharmaceutical Industries: Provides precise filtration for wastewater and process liquids, ensuring compliance with environmental regulations and process requirements.

- Food and Beverage Industry: Offers reliable filtration of liquids to maintain product quality and safety standards.

- Petrochemical and Oil Refining: Efficiently filters oils, fuels, and petrochemical liquids, ensuring the removal of impurities that could affect product quality and machinery performance.

Related Products