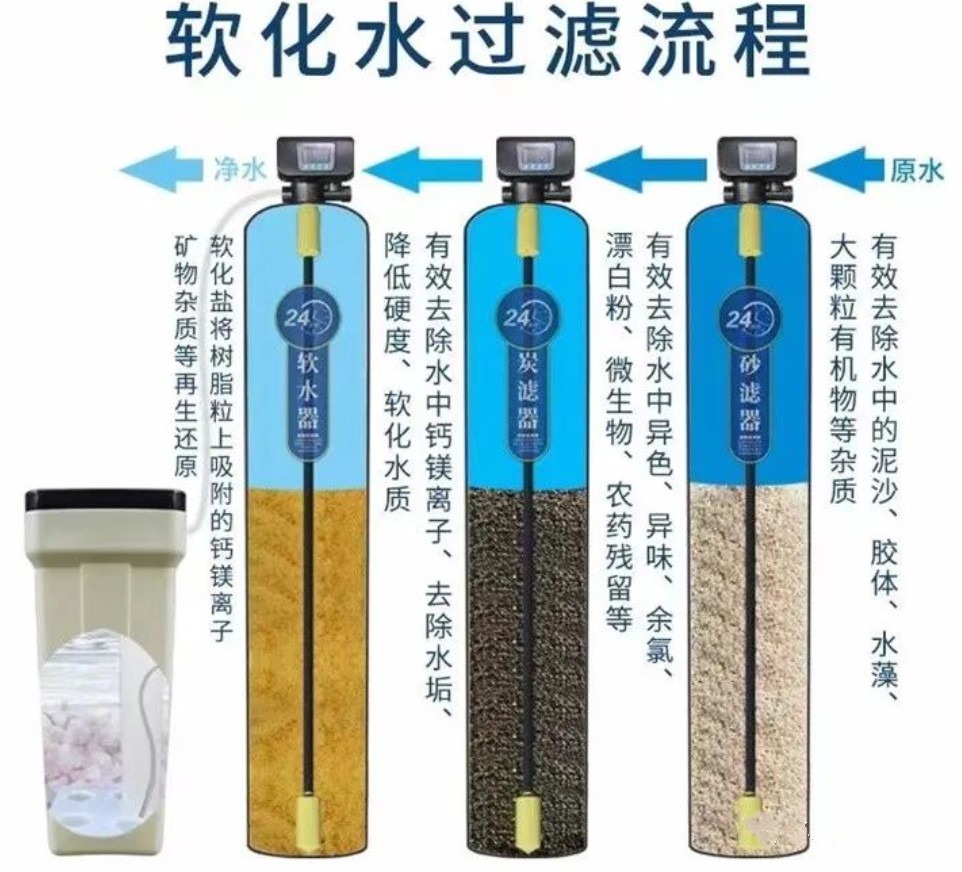

Softeners

We use potassium ions on ion exchange resin to exchange chlorite in water to reduce water hardness and carry out ion exchange resin recycling with water-softening salt. Water-softening salt is also called an ion exchange resin rejuvenator.

Reverse osmosis (RO) plant

Choose a 5μm PP melt blown cartridge, mainly used to remove the former processing treatment system that did not remove the neat particulate matter beyond 5μm, block the first three filtering operations lost in the process of filtering material, and maintain the RO membrane.

The filter cartridge can not reach the normal use standard and will endanger the regular operation standard of the membrane, generally every 3-4 months to remove and replace the filter cartridge.

Detailed introduction of RO reverse osmosis system

The RO reverse osmosis plant mainly contains a multi-level high-pressure cleaning pump. RO membrane components. Membrane housing (high-pressure vessel). Support frame, etc. Its specific function is to remove the residue in the water, and the application of water to meet the application regulations.

RO reverse osmosis device

The high-pressure cleaning pump raises the working pressure of the water output from the security filtration unit to the pressure of RO and subsequently distributes it evenly to the high-pressure vessel.

The flowing water is separated by the RO membrane and produces 2 flowing glasses of water in the high-pressure vessel.

A portion of the water produces pure water according to the membrane, while the remaining carbonates and solid residues are dwelled and extracted to produce concentrated water, which in turn completes the separation of organic matter from the water.

Pure water is discharged from each high-pressure vessel configured with RO membranes, and subsequently discharged into the pure storage tank according to the vapor flow meter discharge equipment inlet and outlet, and concentrated water is discharged from the concentrated water inlet and outlet of the high-pressure vessel.

Reverse osmosis membrane salt removal principle: semi-permeable membrane outer skin covers a lot of very thin membrane pores, membrane surface layer can selectively absorb a layer of water, the amount of salt material concentration by the membrane back, the higher the positive ions, membrane pores around the water in RO reverse osmosis working pressure, according to the membrane capillary discharge of pure water, to do the purpose of salt removal.

The inner diameter of the RO membrane is 1.0nm, thus RO membrane can remove at least one of the germs Pseudomonas aeruginosa (3000×10-10m); it can also filter various viruses, such as a cold virus (800×10-10m), encephalitis virus infection (200×10-10m); and even filter pyrogen (10-500×10-10m).

RO plant advantages

The selection of the original imported series of products iron-carbon packing elimination membrane and imported goods Korakor stainless steel pump, the main performance in the field of water percolation adaptability, salt removal rate, service life, etc. is good.

RO plant compact structure, easy maintenance, a small total area, high water production rate.

No change in the production of pure water and low energy consumption.

No acid, alkali, or other sewage discharge, belongs to the new type of environmental protection and energy-saving equipment.

Maintenance of RO reverse osmosis plant

1. Record daily water quality testing and major parameters of facility operation, and immediately deal with abnormalities. Daily check and record the redox potential of pure water, working pressure at each point, in and out of water flow, and other key parameters on time.

2. According to the actual situation of the construction site and the water production rate, add the rejuvenator in the salt tank on time and set the rejuvenation time. Generally, add once every 3-4 days.

3. Immediately remove and replace the security personnel filter core. (Generally, dismantle and replace every 3-6 months)

4. Often scrub the equipment, and maintain the facility clean.

5. Often detect whether the pipeline is water seepage and early treatment.

6. Ensure the normal power supply and distribution of the facility. In special cases, power and water outages must be regulated again for the length of the equipment, especially the length of the recreation after the power outage.

7. It is strictly forbidden for irrelevant staff to touch the keys of the electrical control system and the gate valves of the pipeline parts to avoid operation errors and make the equipment unable to be applied normally.

Emergency measures

When the RO plant power fails or the main valve, membrane, and other components of the production and manufacture of pure water are destroyed, can not produce pure water, you can open the softening water treatment valve, and apply it to soften the water treatment again to ensure that the normal operation of water equipment without problems.

This type of approach is based on the specific provisions of the water plant.

① When the RO plantseepage is more serious, you should immediately turn off the equipment seepage power switch, and close the program, notify the service provider to solve it.

② In the whole process of water treatment, the membrane after the air pressure table indicates that exceeds 1.5mpa. When the electrical conductivity exceeds 15us/cm or the produced water body exceeds the specification, the epoxy resin should be removed and replaced immediately. Membrane. Activated carbon and other consumables.

Consumables removal and replacement shows

Because the consumables are quartz sand. Activated carbon. Softening resin is granular pieces, and deposition is very easy to produce porous material, for the long-term sex breeding of germs brought to grow natural environment.

At the same time, activated carbon. The softening resin has a certain contrast of absorption, and the filtering effect is reduced after long-term application.

When the cleaning and recreation can not achieve the actual effect of the preparation treatment, it can be removed and replaced to ensure the water body of RO membrane components.

If all standards are met, the application time of quartz sand is 10-24 months, the application time of activated carbon is 10-12 months, the application time of epoxy resin is 10-12 months, the application time of high precision filter core is 3-6 months, and the application cycle time of RO membrane is about 12 months.

Epoxy resin recycles cycle time: Normally, the epoxy resin recycle cycle time is 1-3 days.

A few hidden factors: Before you buy the equipment, you do get to know the price of the equipment, but it is very imprudent to make an independent decision about whether to buy the system or not.

Today, I will take a look at the price of the RO plant by what factors to decide.

Water resources body of water

Because the level of environmental pollution of water bodies in different regions is not the same, the selected sewage treatment process also has a very big difference. Complete sets of equipment for reverse osmosis plants can be based on the local water body to select a scientific and reasonable process treatment.

In the region of poor water bodies, the sewage treatment process is higher, and the equipment is equipped with spare parts characteristics will be enhanced. Thus, the price of equipment for poor water bodies is higher.

Production materials

In order to ensure that the amount of water output water body in line with the regulations, complete sets of equipment reverse osmosis system is generally selected stainless steel plate as raw materials, corrosion resistance, not easy to rust, reasonable to prevent pure water, and other pollutants touching, resulting in secondary pollution.

The raw material production and manufacture of equipment with long service life, are more expensive than other general raw materials.

Water production rate

According to the need for complete sets of plant reverse osmosis plant water production rate. The different water production rates can be divided into the system, small and medium-sized systems, and large-size systems. The larger the scale of operation of the system, the greater the working capital invested in pure water equipment plant capital.