تستهدف أنظمة تربية الأحياء المائية البحرية المعاد تدويرها (RAS) الأنواع عالية الجودة وعالية الكثافة والقيمة مثل الهامور والروبيان وأذن البحر. ومن خلال ضبط النظام في الداخل، يمكن إدارة العوامل الخارجية مثل تلوث المياه وتغيرات الطقس بشكل أكثر فعالية. الهدف هو تحقيق كثافة عالية، وكفاءة عالية، وتكلفة منخفضة، وتلوث منخفض، والأتمتة، والإنتاج في غير موسمه.

22 أكتوبر 2024

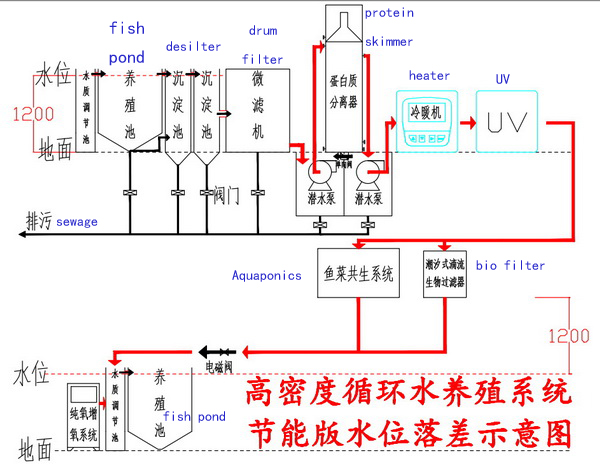

مكونات النظام

نظام الترشيح الميكانيكي

يعد هذا جزءًا أساسيًا من نظام RAS البحري، حيث يشتمل على معدات مثل المرشحات الدقيقة وكاشطات البروتين. تعمل المرشحات الدقيقة على إزالة المعلقات الصلبة الكبيرة من الماء، بينما تقوم كاشطات البروتين بتصفية الجزيئات الدقيقة بشكل فعال وتزيد بشكل كبير من مستويات الأكسجين المذاب في الماء.

نظام الترشيح البيولوجي

يعد نظام الترشيح البيولوجي هو المكون الأساسي لـ RAS. ونظرًا لأن تبادل المياه يكون ضئيلًا أو حتى غير موجود، فإن كثافات التخزين العالية يمكن أن تؤدي إلى زيادات سريعة في مستويات الأمونيا والنتريت. يستخدم نظام الترشيح البيولوجي وسائط الترشيح في المرشحات الحيوية لزراعة البكتيريا المفيدة التي تحلل هذه المواد السامة، مما يضمن بيئة مائية آمنة.

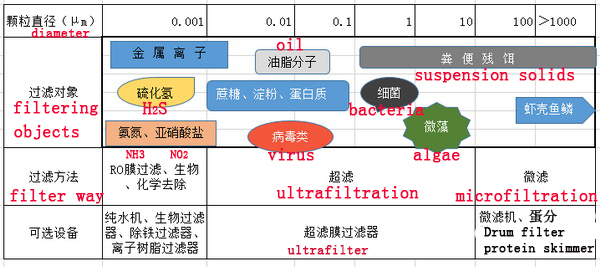

العلاقة بين معدات معالجة المياه والمواد

وفيما يلي بيان لمعدات الترشيح الرئيسية المستخدمة في أنظمة تربية الأحياء المائية الصناعية ووظائف كل منها:

| معدات | وظيفة |

| ميكروفلتر | يزيل المعلقات الصلبة |

| مقشدة البروتين | يقوم بتصفية الجزيئات الدقيقة ويؤكسج الماء |

| المرشحات الحيوية | يزرع البكتيريا المفيدة لتحلل الأمونيا والنتريت |

مقدمة تفصيلية للمعدات

ميكروفلتر

يتم استخدام الفلتر الدقيق في المرحلة الأولى من الترشيح، بهدف إزالة الجزيئات الكبيرة مثل براز الأسماك والروبيان من الماء. يجب تصفية هذه المعلقات الصلبة على الفور لمنع البكتيريا من تحللها إلى مواد سامة مثل الأمونيا والنتريت.

مقشدة البروتين

تؤدي مقشدة البروتين وظائف متعددة: فهي لا تقوم بتصفية الجزيئات الدقيقة فحسب، بل تقوم أيضًا بتزويد الماء بالأكسجين عبر الفقاعات العديدة التي ينتجها. وبالتالي، في حالة وجود مقشدة البروتين، قد لا تكون هناك حاجة إلى معدات تهوية إضافية.

المرشحات الحيوية

تم تجهيز الفلتر الحيوي بوسائط ترشيح تستضيف البكتيريا المفيدة المستخدمة لتحليل المواد السامة مثل الأمونيا والنتريت، مما يضمن بيئة آمنة ومستقرة لتربية الأحياء المائية.

أنظمة حاسمة أخرى

نظام التحكم في درجة الحرارة

يعد نظام التحكم في درجة الحرارة جزءًا حيويًا من RAS وعادةً ما يستخدم مضخات حرارية أو مبردات. وفي المناطق الشمالية، يمكن أيضًا استخدام الغلايات الآلية. عند اختيار معدات التحكم في درجة الحرارة، يجب مراعاة ظروف العزل لمنشآت التربية وأحواض الأسماك. يعمل النظام عن طريق ضبط درجة حرارة الماء تدريجياً عبر دورات متعددة، بدلاً من الوصول إلى درجة الحرارة المستهدفة دفعة واحدة.

نظام التطهير

للوقاية من الفيروسات والتهديدات البكتيرية، لا غنى عن نظام التطهير. عادةً، يتم استخدام الأوزون جنبًا إلى جنب مع كاشطة البروتين، مما يحول الكاشطة بشكل فعال إلى برج خلط الأوزون. ومع ذلك، فإن استخدام الأوزون على المدى الطويل يمكن أن يؤثر سلبًا على الفلتر الحيوي. لذلك، بالنسبة لأنظمة إعادة تدوير المياه على المدى الطويل، يوصى باستخدام أجهزة التعقيم بالأشعة فوق البنفسجية لتطهير المياه.

التحكم في الملوحة ودرجة الحموضة

التحكم في الملوحة

يعد الحفاظ على مستويات مناسبة من الملوحة أمرًا بالغ الأهمية للكائنات البحرية، وخاصة القشريات مثل الجمبري وسرطان البحر التي تتطلب محتوى معدنيًا عاليًا من أجل طرح الريش. ولذلك، فإن تحقيق التوازن بين الأيونات المختلفة في الماء يعد مهمة إدارية حاسمة.

التحكم في درجة الحموضة

يعد الرقم الهيدروجيني للمياه أمرًا حيويًا لصحة الكائنات المائية ويتأثر بعدة عوامل، بما في ذلك الأكسجين المذاب وتكوين الطحالب ودرجة الحرارة. يعد الحفاظ على توازن الرقم الهيدروجيني الديناميكي أمرًا ضروريًا لتعزيز ظروف النمو المستقرة. إن موازنة هذه المعلمات تضمن الوظائف الأساسية لنظام RAS البحري.

اعتبارات تصميم النظام

خلال مرحلة التصميم، يجب تقييم عوامل مثل الظروف الخاصة بالموقع، وكثافات التخزين، وغيرها من المعالم ذات الصلة بشكل شامل. والهدف هو تحقيق أقصى قدر من كفاءة الطاقة والاستدامة البيئية مع توفير كفاءة إنتاج عالية. يمكن لنظام RAS المصمم جيدًا أن يعزز الإنتاج بشكل كبير، ويقلل تكاليف التشغيل، ويقلل التأثير البيئي.

حالة التطبيق العملي

وفي منشأة لتربية الأحياء المائية الصناعية البحرية تركز على تربية الهامور، تم استكمال تركيب المرشحات الدقيقة وكاشطات البروتين والمرشحات الحيوية بأنظمة التحكم في درجة الحرارة والتعقيم بالأشعة فوق البنفسجية لضمان استقرار جودة المياه ودرجة الحرارة. وفي غضون عام واحد، تحسن معدل البقاء على قيد الحياة ومعدل نمو أسماك الهامور بشكل ملحوظ، مما أدى إلى تحقيق أهداف الزراعة عالية الكثافة والقيمة العالية مع إدارة التكاليف بشكل فعال.

تحقق أنظمة تربية الأحياء المائية البحرية المعاد تدويرها (RAS) تحكمًا بيئيًا دقيقًا من خلال الاستخدام الفعال للترشيح الميكانيكي والبيولوجي، بالإضافة إلى أنظمة درجة الحرارة والتطهير. وهذا لا يعزز جودة المنتج والإنتاجية فحسب، بل يقلل أيضًا من التلوث ويزيد من الكفاءة الاقتصادية. ومع التقدم التكنولوجي المستمر، سوف تلعب RAS البحرية دورًا متزايد الأهمية في صناعة تربية الأحياء المائية.

تحليل مبدأ الهيكل والترشيح لخراطيش مرشح الجروح

2 يناير 2025

تعليمات التشغيل التفصيلية لأنظمة الجرعات الأوتوماتيكية

26 ديسمبر 2024

خصائص وتطبيقات المرشحات الدقيقة

19 ديسمبر 2024

فهم ملح تليين المياه: المبادئ والخصائص ودليل الاستخدام

12 ديسمبر 2024