There are many brands in the water purification industry, and the water treatment methods are complicated. Today, from a technical point of view, you are very clear about various water purification technologies, configurations, advantages and disadvantages.

1. Principles of household and commercial water purifiers

According to the accuracy of the filter aperture of the filter membrane and the ability to remove dissolved ions, water purification membranes include four categories: microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. The main filtration methods for direct drinking water are only three categories: ultrafiltration, nanofiltration, and reverse osmosis.

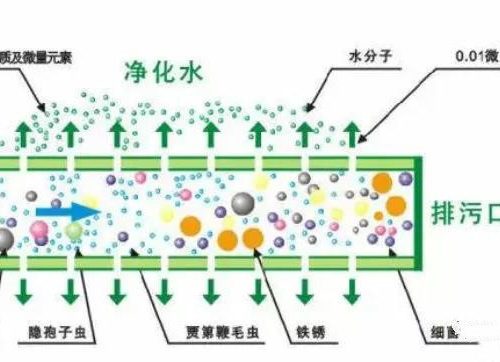

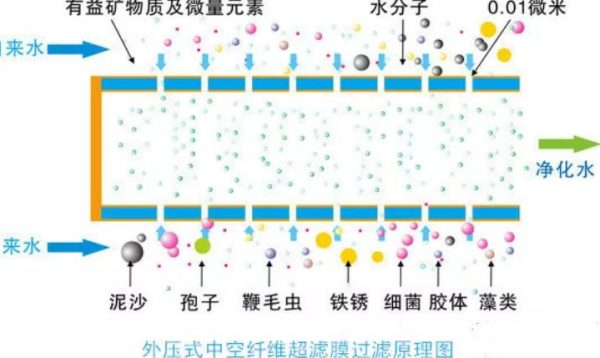

Hollow fiber ultrafiltration membrane filament: 0.5-2.0mm, inner diameter 0.3-1.4mm, the hollow fiber tube wall is covered with micropores, the filtration accuracy is 0.5-0.01 microns, and the pore size can intercept the molecular weight of the material from several thousand to several hundred thousand. .

The raw water flows under pressure on the outside of the membrane or the inner cavity to form an external pressure type and an internal pressure type respectively.

Ultrafiltration is a dynamic filtration process. The retained substances can be removed with concentration without clogging the membrane surface, and it can run continuously for a long time.

Ultrafiltration membrane is one of the first polymer separation membranes developed, which can remove bacteria, colloids, organic matter and other impurities larger than 0.01 microns.

1.11 Internal pressure ultrafiltration membrane and principle

1.12 External pressure ultrafiltration membrane and principle

1.2 Nanofiltration membrane (NF)

Nanofiltration (Nanofiltration) is a membrane separation technology between ultrafiltration and reverse osmosis.

Its molecular weight cut-off is in the range of 80-1000 and the pore size is 1 nanometer, so it is called nanofiltration.

Nanofiltration technology is a membrane separation technology separated from RO technology, and is the continuation and development branch of ultra-low pressure RO technology.

For a long time in the past, nanofiltration membranes have been called ultra-low pressure reverse osmosis membranes (LPRO: Low Pressure Reverse Osmosis).

Now, nanofiltration technology has been separated from reverse osmosis technology and has become an intermediate between ultrafiltration and reverse osmosis.

The independent separation technology between technologies has been widely used in drinking water preparation, medical water preparation, food industry, environmental protection and many other fields, and has become an important branch of membrane separation technology.

Principle: Like the separation process of ultrafiltration and reverse osmosis membranes, nanofiltration membranes are also membrane separation processes driven by pressure difference, which is an irreversible process.

The separation mechanism can be described using charge models (space charge model and fixed charge model), pore model, and electrostatic repulsion and three-dimensional obstruction models that have only been proposed in recent years.

Advantages: Compared with other membrane separation processes, one advantage of nanofiltration is that it can retain small molecular weight organics and high-valent ions that pass through the ultrafiltration membrane, and it can also dialyze some of the inorganic salts and minerals retained by the reverse osmosis membrane-that is Enables “concentration” and desalination to proceed simultaneously.

It can maximize the removal of all pollutants in the water and retain the proper amount of minerals required by the human body.

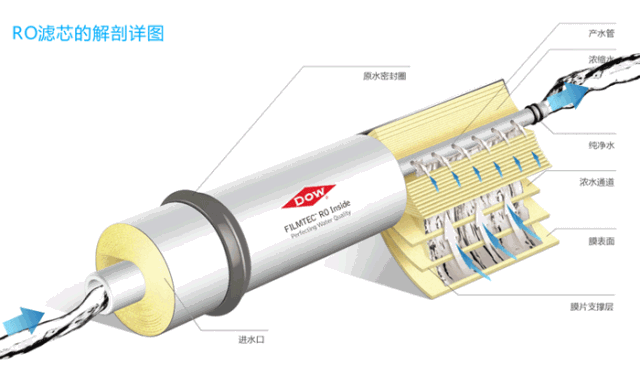

RO is the abbreviation of Reverse Osmosis Membrane in English.

The general flow of water is from low concentration to high concentration.

Once the water is pressurized, it will flow from high concentration to low concentration, which is also called reverse osmosis.

Since the pore size of the RO membrane is five millionths (0.0001 micron) of the hair, it is generally invisible to the naked eye, and bacteria and viruses are 5000 times that of it.

Therefore, only water molecules can pass through, and any other impurities, ions, and Heavy metals are discharged from the waste water pipe, and the product water is pure water.

All seawater desalination processes and astronaut wastewater recovery and treatment use this method, so RO membranes are also known as high-tech “artificial kidneys” outside of the body.

At present, domestic and foreign, medical, military and civilian fields use top RO membranes for polymer filtration.

The year-on-year growth rate of reverse osmosis water purification equipment was as high as 77.6%.

In the future, reverse osmosis membrane treatment technology will become the most mainstream product technology.

2. Auxiliary filter material of water purifier

The main purification method of water treatment is membrane filtration technology, but the auxiliary filter material is also very important. Its function is to remove some impurities in the water at low cost and to protect the main high-precision filter membrane.

Auxiliary filter materials include but are not limited to: activated carbon, KDF, resin, PP cartridge, metal filter screen, quartz sand, etc. as auxiliary water purification means to achieve the purpose of comprehensive treatment.

The PP cartridge filter element is made of polypropylene (PP) by hot melt, and its precision is 1um to 5um. It is a filter element with high efficiency, low pressure difference, long service life and wide applicability.

Main function: Screening out physical pollutants larger than the diameter of the filter hole through logistics interception. Removal of particulate impurities larger than 5 microns in the water, such as suspended solids, sediment, bloodworms, rust, colloids and other large-volume substances to reduce water The turbidity.

Scope of use: Widely use pure water, food and drinking water pre-filtration treatment; with RO reverse osmosis membrane, nanofiltration membrane, ultrafiltration membrane, etc. as pre-filtration pretreatment.

Replacement cycle: The treated water volume is generally 5 tons, and the replacement cycle is 3-6 months, depending on the source water quality and water consumption.

2.2 Activated carbon

Manufacturing process: Water treatment activated carbon is generally made from high-quality coconut shells, refined through a series of production processes, and has a black appearance.

The advantage is that the pore structure is developed, the specific surface area is large, and the adsorption performance is strong.

The expanded area of the filter pores of 1 gram of coconut shell activated carbon is about 2000 square meters.

The reservoir layer has low resistance, stable chemical properties and easy regeneration.

According to needs, it can be made into powder, granule, sintered rod or fiber.

Different water treatment plants are suitable for different activated carbon properties

Main function: Removal of residual chlorine, different colors, odors, heavy metals and other toxic and harmful substances through super adsorption capacity, and can improve the taste of water.

Range of application: It is widely used in the treatment process of pure water, food and drinking water; with nanofiltration membrane, RO reverse osmosis membrane, ultrafiltration membrane, etc. as pre-filtration pretreatment, etc.

Brief introduction: Softening means reducing the hardness of water. The softened water system consists of three parts, namely the ion exchange part, the salt regeneration part and the control part.

Ion exchange technology is the working principle of the softening system. Its main body is ion exchange resin.

Since the hardness of water is mainly formed and expressed by calcium and magnesium, cation exchange resins are generally used to remove Ca2+ and Mg2+ in the water (the main components of scale formation). ) After replacement, with the increase of Ca2+ and Mg2+ in the resin, the efficiency of removing Ca2+ and Mg2+ by the resin gradually decreases.

Therefore, when the water softening equipment is used for a period of time, it is necessary to regenerate the resin with the 25% concentration NaCl regeneration part to restore the efficiency of the resin and increase the service life of the resin.

The control part can realize the automatic operation of the whole system, and automatically regenerate salt according to the running time of the system or the amount of water passed.

2.4 Silicon Phosphorus Crystal

Silicon-phosphorus crystals are glassy pellets made of active ingredients such as soda, phosphoric acid, calcium carbonate, etc., which are fired at 1200-1700°C with high temperature technology.

It has played a positive role in the anti-corrosion and scale inhibition of the water system and the extension of the service life of the equipment.

2.5 Water softener (high purity sodium chloride)

Soft water salt, also known as ion exchange resin regeneration agent. Its main chemical component is sodium chloride (NaCl), the content is above 99.5%, and the general shape is pellets.

When the resin of the soft water equipment absorbs more and more impurities, its adsorption capacity will gradually decrease. To remove the impurities absorbed by the resin (mainly calcium Ca, magnesium Mg ions), sodium ions (Na) need to be used through backwashing The method is to replace the impurity ions (mainly calcium Ca, magnesium Mg ions) adsorbed by the resin through ion exchange to restore the adsorption capacity of the resin. This process is also called ion exchange resin regeneration.

2.6 Other auxiliary filter materials

Including metal filter, quartz sand, mineralized ball, medical stone, etc.