Preparation before installation and replacement?

The main sources of pollution during the first installation of new equipment are two main categories.

First, various metal debris and PVC debris from the welding pipeline will cause irreversible physical scratches to the diaphragm if not handled.

Solution: Fully flush the equipment to ensure that the debris in the pipeline is flushed away.

Second, the ratio of anti-corrosion coating in the water tank is not uniform, resulting in the release of organic matter, which directly pollutes the membrane element.

Solution: Soak the water tank content directly with pH=2 hydrochloric acid for 24 hours, and drain all the water after soaking.

Main considerations when replacing the membrane of old equipment.

First, after the old membrane is removed, the pipeline needs to be cleaned carefully, and a mop can be tied with a wire to wipe the inner wall of the membrane shell. Prevent the residual impurities in the pipeline from polluting the new membrane.

Second, before the installation of the new membrane, the security filter element will be replaced. To avoid further contamination of the membrane by the contaminated cartridge.

02

Installation method illustration

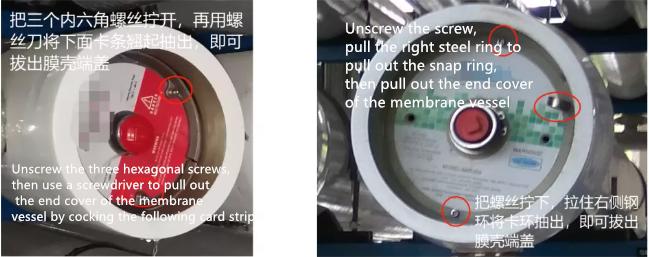

1. Disassemble the end cover of the membrane vessel

There are mainly two types of membrane housing end caps on the market, one is fixed with three tabs and the other is fixed with a snap ring.

The end caps can be disassembled by following the above diagram and using the corresponding tools.

2. Flush the membrane vessel

Before opening the end cover of the membrane shell, turn on the low-pressure flushing pump for flushing.

After opening the end cover of the membrane shell, flush the inside of the membrane shell again with a water pipe.

If there are stubborn contaminants, you can use a mop tied with a long wire to clean the inside of the membrane shell to ensure that the inside of the membrane shell is clean before installing the membrane. In particular, large particles of contaminants visible to the naked eye should not be present.

3. Membrane and membrane vessel direction

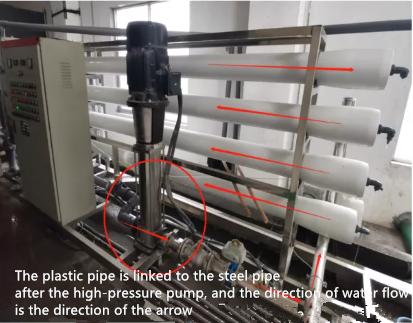

Plastic pipe has a low-pressure bearing and steel pipe has a high-pressure bearing, the direction of water flow in membrane shell can be determined by a high-pressure pump.

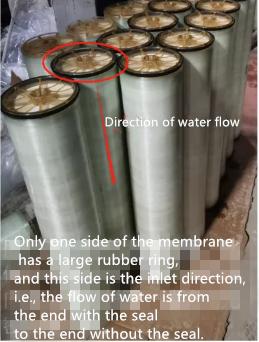

The membrane is oriented as shown in the figure.

4. Membrane direction and installation push-in

After determining the direction of water flow, push one end of the membrane without sealing into the membrane shell first, leaving a distance of about 15cm from the mouth of the membrane shell to stop.

Apply diluted glycerin lubrication at the large rubber ring and the central tube rubber ring, insert another membrane in the same direction and push it in parallel, and so on repeatedly.

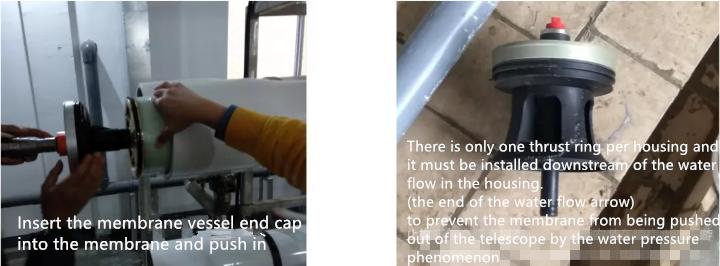

5. Install the membrane vessel end cover

Reinstall the membrane shell end cover according to the structure when disassembling the membrane shell end cover.

If it is hard, use a wooden block on the end cover of the membrane shell and hit it with a hammer to reset it, but do not hit the end cover of the membrane shell directly with a hammer.

03

Flushing before commissioning

After the new RO membrane is installed, it should be filled with clean and oxidant-free water immediately, flushed with 2-4Bar low pressure for 1 hour, and all concentrated water and produced water should be drained, not directly into the secondary RO inlet or back to the primary RO inlet.

Then soak the RO system for more than 12 hours, after fully wetting, start the high-pressure pump to produce water (boosting speed <0.7Bar/sec), but the produced water and concentrated water should be drained within the first 24 hours, do not go directly to the secondary RO inlet or back to the primary RO inlet.

If the produced water within the first 24 hours of the new RO membrane is fed directly into the secondary RO membrane, it may cause irreversible flux loss in the secondary RO membrane.

For wastewater reuse systems, to avoid potential fouling by unknown organic contaminants in the effluent, it is best to complete the commissioning of the RO membrane system with a clean commissioning water source and then gradually switch to a 100% effluent source on a proportional basis.

A clean commissioning source is essential for wastewater reuse systems to reduce initial contamination.