Boiler water softener system is a raw water pretreatment device for boilers with a long scale, removing calcium and magnesium ions in raw water as well as elements that cause long scale in boilers.

March 22, 2022

Boiler equipment can be safe and economic operation, water quality treatment is very important. But sometimes there will be boiler softening water failure, what causes it? How to deal with it?

Boiler water softening failure phenomenon and treatment methods:

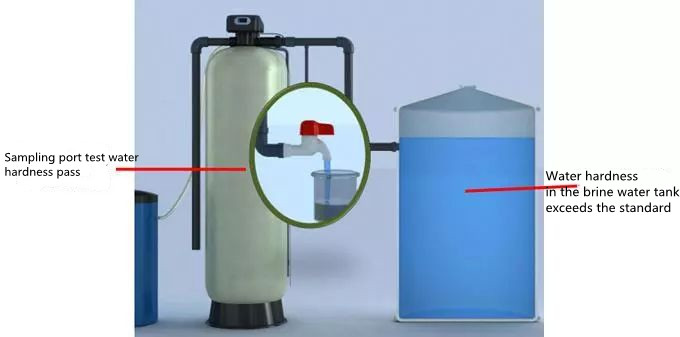

Water softening equipment water qualified, water softening tank water exceeds the standard

In the water softening equipment sampling port test is qualified, but the water hardness in the water softening tank exceeds the standard, indicating that the water softening equipment water effect is not stable, there has been excessive water injected into the water softening tank.

The reasons may be.

1, regeneration cycle set too large (time type), or flowmeter failure caused by inaccurate measurement (flow type), so that the resin should have been regenerated when not regenerated in a timely manner, resulting in the injection of oversized water into the soft water tank. If the impeller is stuck by rust or the water quality is too dirty to make the impeller rotation is not smooth.

2, the positive washing time is short, so the waste brine should have been washed off in the positive washing was partially brought to the soft water tank.

3, the feed water pressure instability caused by too little salt tank replenishment, too little salt absorption, is not enough to wash, any of the above can cause the regeneration of the water hardness exceeds the standard, affecting the soft water tank water quality.

4, salt tank in the salt is very little when not added in time, resulting in a regeneration effect is not good.

5, improper operation, in a regeneration process, to close the water valve.

6、The bypass ball valve is open or leaking.

The sampling port in the water softening equipment repeatedly tested, are not qualified

The reasons maybe

1, newly installed water softening equipment for the first time test water hardness exceeds the standard.

※ The centre tube O-ring does not form a seal.

※ The length and outside diameter of the centre tube is in line with the requirements (glued under the centre tube of the water cloth into the tank).

※ The end of the centre tube should not be higher than the tank mouth by 2mm and lower than the tank mouth by 5mm.

Note: The centre pipe of national standard and American standard is different, and the connection size of the valve and centre pipe must adopt the same standard.

※ Forget to install the centre pipe O-ring or O-ring falls off during installation.

※ The centre tube O-ring is broken.

※ The centre pipe is broken or cracked.

2、The ratio of feedwater TDS value to resin layer height is too large. The feedwater hardness of the first-stage sodium ion exchanger requires <6.5mmol/L.

3, feedwater TDS value and resin exchange capacity ratio is too large.

4、Operating flow rate is too fast. It is strictly prohibited to work for a long time at the maximum flow rate allowed by the equipment.

5、Water inlet and outlet are reversed.

Note: GB/T18300 in the downstream regeneration of fixed bed operating flow rate of 20 ~ 30m / h, its upper limit for the maximum instantaneous, is strictly prohibited in this flow rate of long-term work.

In the use of water softening, equipment soft water hardness exceeds the standard

The main reasons are

1, the ratio of the feedwater TDS value and the height of the resin layer or resin exchange capacity is too large.

Compared with the initial trial of new resin, in use water softening equipment on the feed water TDS value requirements are more stringent, when the resin layer height of 1.5 meters, the total hardness of 10mmol / L, the feedwater TDS value ≥ 900mg / L, to ensure that soft water hardness ≤ 0.03mmol / L will be more difficult.

2, resin poisoning loss of exchange capacity.

The high content of Fe3+ and Al3+ in the raw water makes the resin poisoning (when the resin becomes dark red), which causes the resin exchange capacity to be reduced and the cycle water volume to be reduced. The cause of the soft water hardness exceeding the standard is a gradual process, not a sudden and obvious exceedance.

3、The resin regeneration is not good, resulting in a gradual reduction of the cycle water production, and the water output is not qualified at the late stage of the set water production cycle.

※ The amount of salt in the salt tank is too low. When the water volume in the salt tank is normal, but the height of salt is less than 1/3 of the height of the water, the brine absorbed in the middle and late stages of the salt absorption step is likely to be unsaturated, resulting in the concentration of brine diluted by the jet streamer being lower than the regeneration requirement, which affects the regeneration effect.

※ The total amount of water in the salt tank is too small. For every 100L of resin in the resin tank, the minimum amount of water required in the salt tank is 40L.

※ Sucking brine is too slow, not enough brine can be sucked in within the normal time.

※ The regeneration flow rate is too fast or the regeneration method is not correct, i.e. the tank is not matched with the injector.

4、A large amount of gas exists in the resin tank. The gas may come from carrying gas in the feed water, or the air backstop valve is not closed properly during the slow washing process.

5、No large grain non-iodized salt is used.

6, backwashing is not complete, the exchange agent is contaminated by suspended matter, there is the phenomenon of clumping, resulting in a partial flow.

7, control valve internal leakage hard: general control valve internal leakage hard, often appear soft water port and wastewater port at the same time out of the water.

These are some boiler softening water failure phenomena and treatment methods, if there are more insights and treatment methods, welcome to leave a message and communicate with each other! The popularization of boiler softening water treatment, to ensure the safe and economic operation of boilers, improve boiler efficiency, extend the service life of boilers, saving energy is of great significance.

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024