What is back pressure?

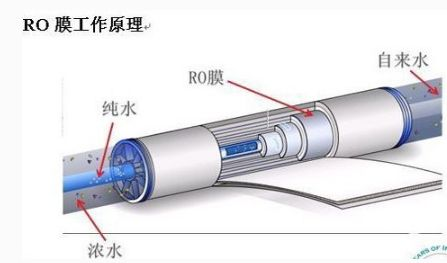

In reverse osmosis water treatment, back pressure refers to a situation where the pressure on the product water side is greater than the pressure on the feed water side. A rolled membrane element resembles a long envelope-like membrane pocket with the open side bonded to a product water center tube containing an open hole. A plurality of membrane pockets are wound onto the same product center so that the feed water stream flows through the outer side of the membrane, allowing fresh water to flow through the membrane into the pockets and then converge into the product water center tube under feed water pressure.

To facilitate the flow of product water inside the membrane pocket, a fabric support layer for product water infusion is sandwiched inside the envelope-shaped membrane pocket; to make the feed water flow evenly over the surface of the membrane pocket and to give a disturbance to the water flow, a spacer layer is sandwiched in the feed water channel between the membrane pocket and the membrane pocket.

The three sides of the membrane pocket are bonded together with a bonding agent. If the pressure on the product water side is greater than the pressure on the feed water side, then these bonding lines will rupture and result in a loss of desalination rate or a significant reduction in the membrane element, so from a safety perspective, reverse osmosis systems cannot have back pressure.

Since reverse osmosis membrane filtration is pressure-driven, there is no back pressure during normal operation, but if the system is shut down normally or in case of failure, the valve is not set or opened properly, then there may be back pressure, so the problem of back pressure must be solved properly.

How does backpressure occur? How to avoid backpressure?

Generally speaking, the technical manual of reverse osmosis membrane has back pressure limit parameters, assuming that the maximum back pressure that reverse osmosis membrane can withstand is 0.1MPa, which is about 1bar, equal to the pressure generated by 10m water column. When reverse osmosis is shut down, the water present in the production pipe will inevitably produce a certain pressure on the water production side of the reverse osmosis membrane, and the higher the production pipe climbs, the higher the pressure will be, and if the production pipe climbs higher than 10 meters, then the back pressure on the water production side of the water production will be enough to cause damage to the membrane. Therefore, the reverse osmosis design process should specify 8 meters as the maximum climbing height of the production pipe, and a check valve should be installed on the production pipe to prevent the water in the production pipe from generating pressure. Sometimes there may be a situation where the check valve is not strict or the climbing height of the production pipe must be high, in this case, the method of installing an evacuation pipe after the check valve of the production pipe can be adopted to prevent the generation of back pressure.

Another type of back pressure is generated due to operational errors. During the operation of reverse osmosis, if the operation is wrong. In the case of water production valve and water discharge valve are not open to turn on the pump, it will cause the system pressure is rising, the pressure on the water production side is rising but the water is not produced. The water production pipeline is usually made of UPVC, if the pressure is too high, the pipeline may cause a safety accident if it bursts. At this time, the operator if the emergency to open the production of the valve to release pressure, you can avoid accidents. If the operator takes the way to stop the pump, then the pressure on the inlet side suddenly decreases and the pressure on the production side is very high, so the high back pressure will immediately cause damage to the membrane. Therefore, designers should also take this into consideration during the design process. A bypass can be added to the side of the discharge valve and a bursting membrane can be installed on the bypass, assuming that the bursting pressure of the bursting membrane is 0.3MPa, so that once the system holds pressure, the pressure on the water production side will automatically burst and release pressure when the pressure exceeds 0.3MPa to prevent further losses.

There are also bursting membrane due to non-standard, less than bursting pressure bursting, or to the bursting pressure does not burst the case, sometimes, field personnel in order to save trouble, directly take the iron plate or other materials to replace the bursting membrane, so that, once the pressure is held, it is really irreparable. So be sure to follow the specifications and do a good job of bursting membrane experiments.

Water treatment equipment site commissioning personnel should also pay attention to the reverse osmosis device operation process, before the start remember to check whether the water production valve and production and discharge valve is open, before the shutdown is also priority to open the production and discharge valve, in order to prevent back pressure accidents.