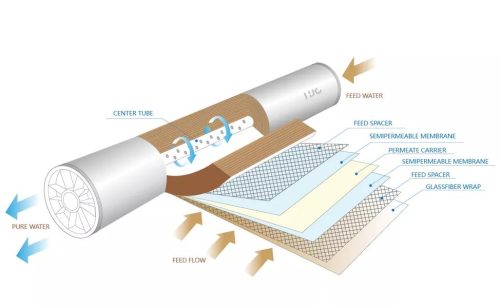

Reverse osmosis technology is based on the principle that other substances cannot pass through a semi-permeable membrane under the effect of osmotic pressure higher than that of the solution, and these substances and water are left behind. The membrane pore size of the RO membrane is very small, so it can effectively remove dissolved salts, colloids, microorganisms, organic matter, etc. from water.

RO system has a high operating cost because of the high-pressure pump and a special scale inhibitor needs to be added. So how can we reduce the operating cost of the RO system?

01 Choose ultra-low pressure reverse osmosis membrane

Conventional reverse osmosis membrane operating pressure is 1.3 ~ 1.5 MPa, ultra-low pressure reverses osmosis membrane operating pressure is about 0.8 MPa or even lower (closely related to the water temperature), can save more than 30% of electricity consumption. For large RO systems, it can basically offset more than 70% of the annual depreciation cost of the membranes, so the savings are even more significant.

02 High-pressure pump with inverter

A high-pressure pump with an inverter can not only slow down the water hammer impact when the pump starts, but also reduce the valve throttling energy consumption by setting a reasonable operating pressure, which can save at least 15% of energy quarterly throughout the year.

03 Reasonable calculation of scale inhibitor dosage

By analyzing the water quality data and optimizing the dosage, we can usually save 20% or even more on the cost of chemicals.

04 Reduce the operating pressure by appropriately increasing the number of membranes

By appropriately increasing the membrane area, the operating pressure of the membrane can be reduced to a certain extent and the electricity consumption can be reduced

05 Environment

Water temperature higher than 45℃ will shorten the service life of the membrane. Generally, the water temperature needs to be controlled below 40℃, and cooling measures should be taken when necessary. For RO systems, wastewater containing strong oxidizing substances or precipitating substances will lead to a shortened membrane life cycle. When designing the system, from its safety point of view, increasing the pretreatment safety margin and adding a protective shutdown design can avoid causing such problems.