Precision filter, also known as security filter, is generally set before the pressure vessel to remove fine particles above 1 degree to meet the requirements of subsequent processes for water intake, and sometimes at the end of the whole water treatment system to prevent fine particles (such as broken resin) from entering the finished water.

July 11, 2023

Precision filtration system (also known as security filter) mostly use stainless steel as a shell, internal filter element (such as PP filter cartridge), mainly used in multi-media pretreatment filtration, reverse osmosis, ultrafiltration and other membrane filtration equipment before. It is used to filter out fine substances (such as tiny quartz sand, activated carbon particles, etc.) to ensure that the filtration accuracy of water quality, and the protective membrane filter elements are not damaged by large particles. The precision level of the filter element installed in the precision filtration device can be divided into 0.5 μ s, 1 μ s, 5 μ s, 10 μ s, etc. According to different use occasions, different filtration accuracy is selected to ensure the effluent accuracy and the safety of the posterior membrane components.

PP cotton, nylon, melt-blown and other different materials are used as filter elements to remove small suspended matter, bacteria and other impurities in the water, so that the raw water quality can meet the water requirements of reverse osmosis membrane.

Technical Principle

Security filter is a precision filter, its working principle is to use PP filter element 5 μ m pores for mechanical filtration. The trace suspended particles, colloids and microorganisms remaining in the water are trapped or adsorbed in the surface and pores of the filter element. With the growth of water production time, the running resistance of the filter element gradually rises due to the pollution of the trapped material. When the water pressure difference between the inlet and outlet reaches 0.1MPa, the filter element should be replaced. The main advantages of security filters are high efficiency, low resistance and easy to replace.

Structure and Principle

The security filter uses the formed filter material, under the action of pressure, make the stock liquid through the filter material, the filter residue remains on the pipe wall, the filter liquid through the filter material out, so as to achieve the purpose of filtration. Structure: filter cloth, filter screen, filter plate, sintered filter tube, wire winding filter element, melt-blown filter element, etc. Because of the different filter material, the filter pore size is not the same. Precision filtration is a filter between sand filter (coarse filtration) and ultrafiltration, and the filtration aperture is generally in the range of 0.5~120 μ m. The filter material of the same form can be divided into different specifications according to the external size. There are two kinds of wire winding filter (also known as honeycomb filter): one is polypropylene fiber-polypropylene skeleton filter, the highest service temperature is 60℃; the other is skimmed cotton fiber-stainless steel skeleton filter, the highest service temperature is 120℃. Melt-blown filter element is a filter material formed by melt-blown process using polypropylene as raw material, with the highest working temperature of 60℃. Precision filtration can remove suspended solids, some colloidal substances and small particles in the water.

Protect

(1) Water source is generally a fixed water source, which cannot be easily changed.

(2) Improve the operation effect of pretreatment, optimize the dosage of flocculant and coagulant aid, select the scale inhibitor suitable for the water source, adjust the pretreatment equipment to achieve the best operation state, strictly follow the requirements of the operating procedures, and ensure that the quality of the pretreatment effluent is qualified.

(3) The selection of the brand filter element with guaranteed quality, not only can extend the service cycle of the filter element, but also can ensure the water quality of the security filter. For example, the GEOsmonics filter element, its filter accuracy is 5 ± 0.5 μ m, using Z. Plex Technology’s GEOsmonics new Purtrex filter element redefines all previous RO pretreatment performance and cartridge construction criteria.Z. Plex technology uses short diameter melt-blown filter elements, wide layer spacing and a three-dimensional fiber matrix Purtrex filter element is particularly suitable for water treatment applications, because fine sediment particles in water treatment applications are easy to prevent reverse osmosis equipment. This filter element is unmatched in the interception of water dirt, the pressure loss is lower, and the service life is longer than most similar filter elements. Under the filter element load-free shell, the fiber and three-dimensional mesh form a variety of pores, which can effectively capture impurities. In the following filter layer, Z. The increasing number of small pores in the fiber structure unique to Plex technology until the center of the filter element maximizes the filter life and sludge removal efficiency.

For accurate micron-scale filtration, the inner core is the last filtration layer. The inner core is a hot melt bond structure with unmatched integrity, downstream cleanliness and rigidity and no need for support core. Similarly, the adhesive exterior coating with strong permeability performance is very smooth, which can prevent the loose fiber from moving, which is critical for applications with high purity requirements.

Features Precision filters have the following characteristics:

.

Can effectively remove the liquid in the suspended matter, rust, etc.

. Can withstand high filtration pressure.

The unique deep mesh structure makes the filter element have a high slag capacity load capacity.

. The filter element can be made from a variety of materials to meet the needs of various fluid filtration.

. The appearance of small volume, large filtration area, small resistance, long service life

Function and Purpose

In order to prevent the suspended particles that are not completely removed or newly generated into the reverse osmosis system, protect the high pressure pump and reverse osmosis membrane, the filter type security filter is usually set before the reverse osmosis water. Generally, the aperture is less than 10 μ m, and it can be designed as 5 μ m or lower according to the actual design situation.

Constituent Part

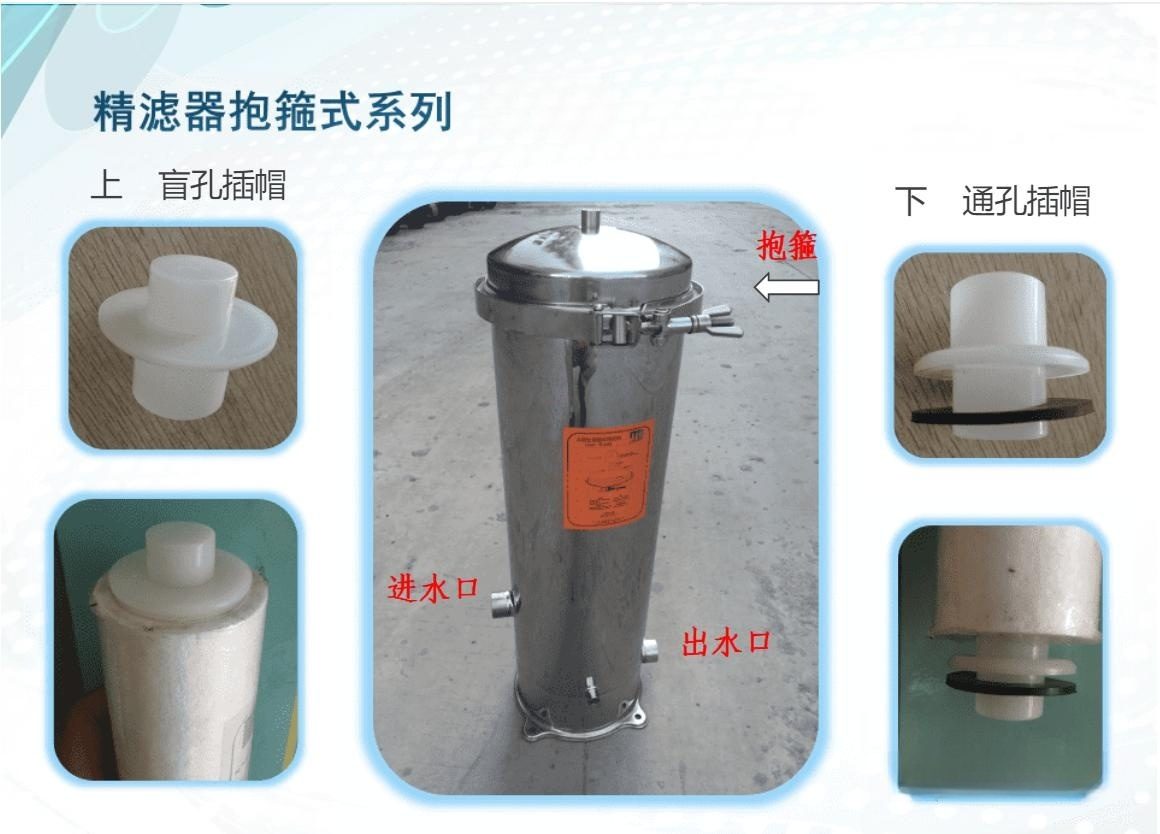

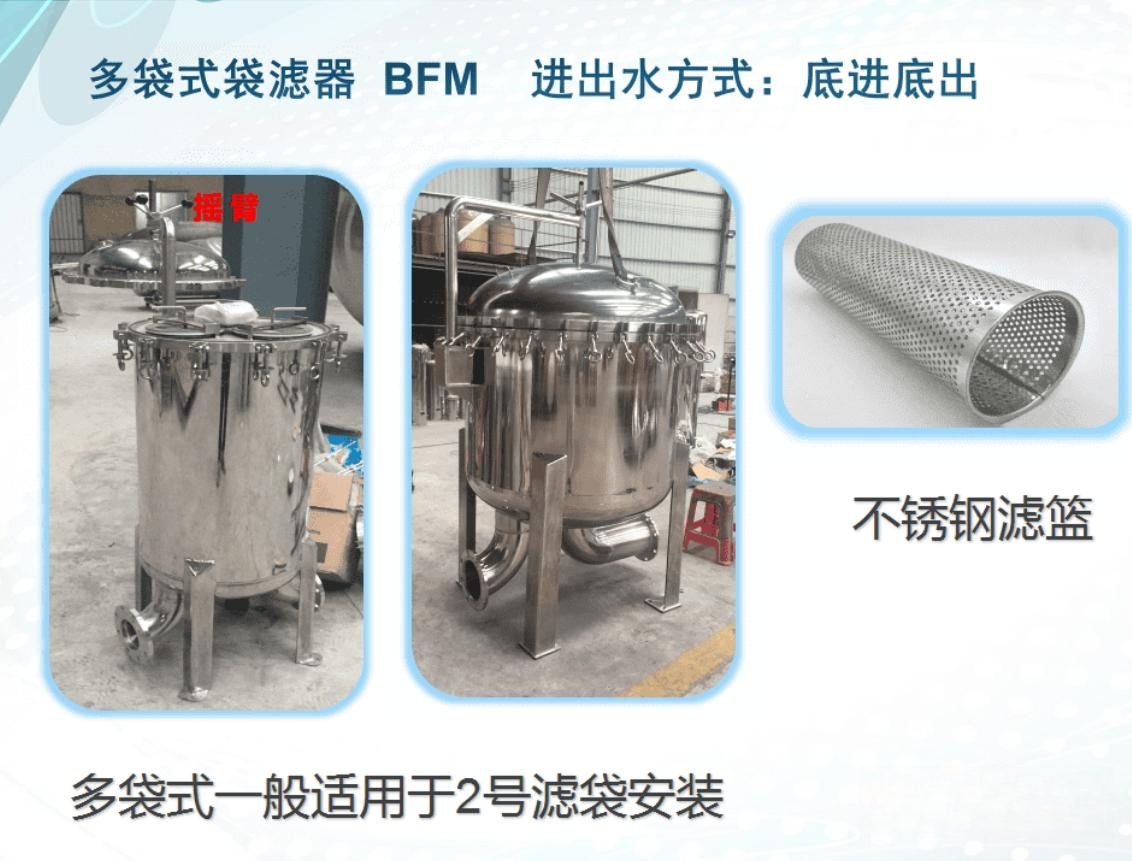

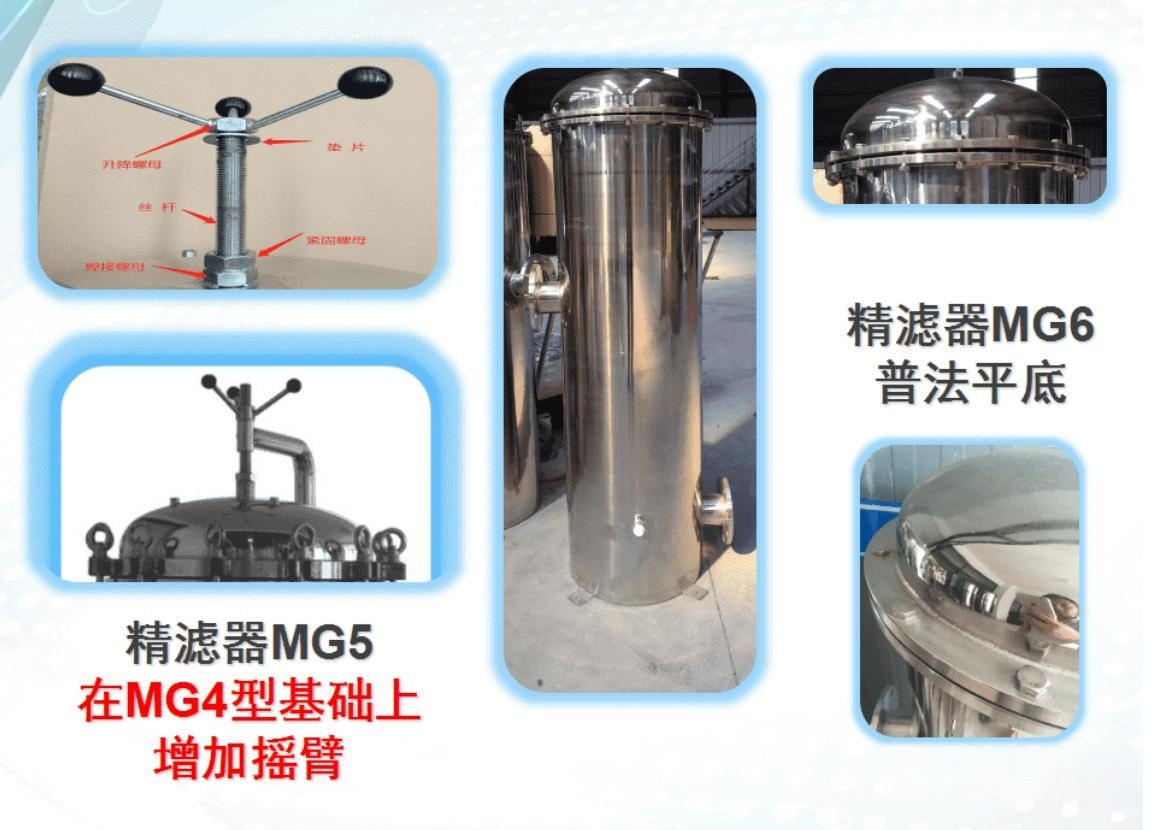

Security filter is mainly composed of filter shell, filter element, etc. Most of the filter shell is composed of R304 stainless steel material, if used in acid and alkali resistance and other special occasions, R316 stainless steel can be used as the shell. It can be divided into flange type and clamp type, and the flange type shell is mainly used in the occasion with large filter flow. The filter element installed in the middle of the filter case is mainly PP filter cotton core, and some occasions can also choose wire filter or activated carbon filter. The number of filter elements can vary from one to dozens, mainly according to the size of the processing capacity to determine.

Common Filter Type

The filter element materials mainly include sintering filter pipe, melt-blown fiber filter element and honeycomb filter element.

Sintering pipe is formed by powder material through sintering, its filter tube material has ceramics, glass sand, plastic and so on. Meltblown fiber filter element is generally made of polypropylene as raw material, after heating and melting, injection, traction and receiving molding. PP filter element with polypropylene as raw material is commonly used. Honeycomb filter element is made of textile fiber roving precision winding on the porous skeleton, polypropylene line around the honeycomb filter element is more commonly used.

Matters need attention

The pressure gauge shall be set for the water inlet and outlet of the security filter. When the water pressure difference between the inlet and outlet reaches the limit value during operation, the filter element shall be replaced in time. Because the cleaning and recovery efficiency of the filter element is low, so it is best to use the disposable filter element.

Method of erection

- Open the package and put it apart

- Install the filter element

- Attach the filter element into the filter tank

- Secure the tank lid and install the exhaust valve.

Technical Parameter

Design pressure: 0.75-1.6Mpa

Design temperature: 20℃ ~120℃

Seal type: O-ring and flat pad

Seal material: nitrile rubber, silicone, fluorine rubber and polytetrafluoroethyl, etc, standard configuration for silicone seal

Interface form: teeth, clamp, GB, HG, DIN, ANSI, JIS standard flanges

Applicable filter element: flat port and 222 and 226 port filter element

Surface treatment: matte spraying, mirror polishing, electropolishing

Filter accuracy: 0.5 μ m- -100 μ m

Material: SUS304 316L

Applied Range

- Nanofiltration (NF), ultrafiltration (UF), reverse osmosis (RO), electrodialysis (EDI) and other system security filtration and terminal filtration;

- Medical injection, large infusion, eye drops, Chinese herbal medicine and other filtration, biological agents extraction, purification and concentration;

- Prefiltration, terminal filtration of high purity water for electronics, microelectronics and semiconductor industry;

4, oil field back water injection, boiler supply water, chemical reagents, liquid organic products, high purity chemicals, concentrated drugs and other filtration;

5, drinking pure water, mineral water, fruit juice, tea drinks, health drinks filtration;

- Filtering of liquor, wine, beer, yellow rice wine and other fruit wine, sterilizing and filtration of pure raw beer (instead of pasteurization);

7, pretreatment and filtration in the process of production and domestic wastewater treatment and water recycling or security filtration;

8, other such as biological engineering, oil refining, printing and dyeing, textile industry water supply and wastewater treatment, scientific research experiment filtration, etc

Applicable industry

The quality of the outlet water meets the food hygiene standards, and can be used for hotels, schools, food factories, beverage factories and families to prepare cold drinks, drinks, as well as as pure water preparation unit device

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024