Under normal circumstances, Rreverse Osmosis Membrane elements can be used for about 2 to 3 years. If you want to extend the service life, you can clean the reverse osmosis membrane elements, which are usually divided into two methods: physical flushing and chemical flushing. When the physical flushing can no longer restore the performance of the reverse osmosis membrane, chemical cleaning should be performed.

November 1, 2021

Cleaning of reverse osmosis membrane

According to experience, if the reverse osmosis device is cleaned every three months or longer. If it is cleaned once every 1-3 months, it is necessary to improve the operating conditions and improve the pretreatment effect.

1 Determine the cleaning situation:

(1) Standardized freshwater production has dropped by more than 10%.

(2) The standardized salt penetration rate has increased by more than 10%.

(3) In order to maintain the normal flow of fresh water, the pressure difference between feed water and concentrated water after temperature calibration has increased by more than 10%.

(4) There are serious pollutants and scales in the internal device.

(5) Before the RO system is not work for a long time.

(6) Routine maintenance of RO system.

Before checking whether to clean the reverse osmosis system, the following other reasons that may cause the above phenomenon should also be comprehensively considered:

☆ The operating pressure drops (the pressure control device fails and the high-pressure pump is abnormal);

☆ The inlet water temperature decreases (heater failure, or seasonal changes cause water temperature to decrease);

☆ Increased salt content of influent;

☆ Abnormal pretreatment;

☆ The concentrated water seeps into the fresh water due to membrane damage, misalignment of the central tube of the tandem membrane element, and inadequate sealing of the O-ring of the pressure vessel.

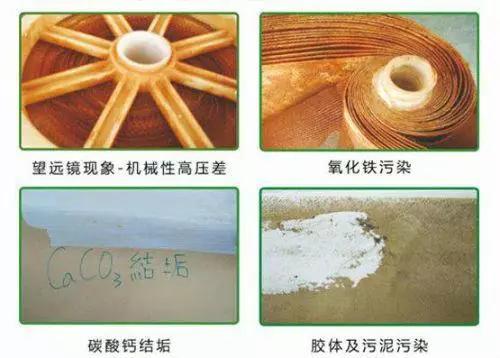

2 pollutants

Common pollutants in reverse osmosis membrane elements mainly include CaCO3, CaSO4, BaSO4, SrSO4, metal oxides, silicon deposits, organic matter and biological slime. When the scale inhibitor dosing system or the acid addition system fails, CaCO3 may be deposited in the membrane elements, and chemical cleaning methods should be adopted for cyclic cleaning or overnight soaking.

3 formula

Different pollutants cause different degrees of damage to the membrane, and different cleaning solutions are used for different pollutants.

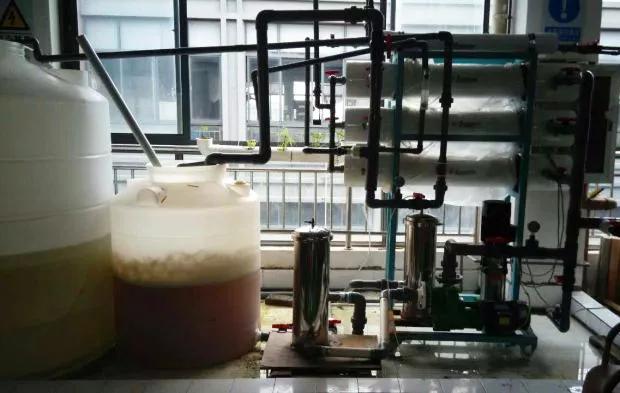

4 cleaning equipment

(1) Reverse osmosis cleaning In Place(CIP) System

It is generally composed of cleaning pump, chemical dosing tank, 5-20um security filter, heater, related pipeline valves and control instruments.

(2)Operation

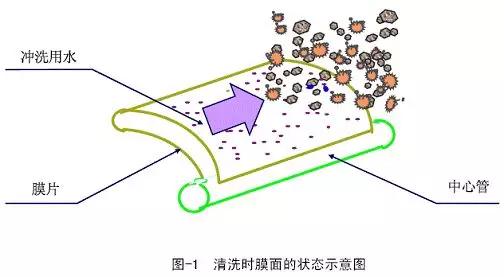

The cleaning methods include static soaking and cyclic cleaning. Static soaking uses cleaning fluid to soak the membrane. The time depends on the degree of pollution, which is approximately 1-15h.

The general steps of cyclic cleaning are:

1 Use a pump to send fresh water from the chemical dosing tank to the pressure vessel, and discharge it for a few minutes.

2 Prepare the cleaning solution with fresh water in the chemical tank

3 Circulate cleaning the pressure vessel with cleaning fluid for 1 hour or reach a predetermined time. The cleaning flow can be determined according to the following table. When the pollution is serious, the cleaning flow can be increased to 150% of the resin in the table. At this time, the cleaning pressure drop is relatively large, and it is generally controlled not to exceed (0.10-0.14MPa)/root membrane element or 0.4MPa/root membrane assembly. At the beginning of the medicine cleaning, use 50% of the flow value in the table to inject the heated cleaning fluid into the pressure vessel to control the pressure so that it can overcome the pressure drop between the inlet and outlet water and there is no fresh water outflow. In order to prevent the cleaning fluid from being diluted, the concentrated water discharge valve can be opened to drain the system water before cleaning. The reverse osmosis system can be cleaned in sections. The cleaning direction is the same as the running direction. Reverse cleaning is not allowed, otherwise it may cause the membrane roll to protrude and damage the membrane element.

4 After the cycle cleaning is completed, clean the chemical tank with fresh water.

5 Rinse the above-mentioned pressure vessel with fresh water.

6 After flushing, run the reverse osmosis system with the fresh water outlet valve open until the fresh water is clean, without foam or cleaning fluid, which usually takes 15-30 minutes.

Replacement of reverse osmosis membrane

After the reverse osmosis equipment has been in normal operation for a period of time, the reverse osmosis membrane elements will be contaminated by suspended solids or insoluble salts that may exist in the feed water, and the following symptoms will appear:

1 The weight of the membrane element of the reverse osmosis equipment increases;

2 The removal rate of RO membrane is significantly increased or decreased;

3 Under standard pressure, the water output of reverse osmosis equipment has dropped significantly;

4 In order to achieve the standard water production, the operating pressure needs to be improved;

5 The pressure drop between the inlet water and the concentrated water of the reverse osmosis equipment increases;

6 Take the membrane element out of the pressure vessel and pour the water on the inlet side of the erected membrane element. If the water cannot flow through the membrane element, it will only overflow from the end surface, indicating that the inlet flow channel is blocked.

Whether it is necessary to replace the reverse osmosis membrane element or not depends on the actual situation。

How to Choose the Right Pure Water Treatment Equipment for Your Needs?

November 10, 2025

How to Choose the Right Pure Water Treatment Equipment for Your Needs? (by ROAGUA – Professional Water Treatment Equipment Manufacturer, China)