The design of ultrapure water plant requires a full understanding of customer needs, selection of the correct process, excellent system manufacturing and standard daily maintenance. Among them, customer needs are the basis, process selection is professional, system manufacturing is the core, and daily maintenance is the key.

November 22, 2023

- Understand the needs and basic situation of customers. Common situations you need to know about are as follows:

Raw water incoming water quality type or standard: such as municipal tap water, surface water, groundwater, river water, lake water, etc. It is best to have a specific water quality test report.

Pure water effluent quality requirements: conductivity or resistivity standards, whether there are any special index requirements.

Pure water output requirements: Based on various conditions such as per capita water consumption, water consumption per hour of production, daily peak water consumption, etc., T/H or T/D is expressed.

Process requirements for pure water: different processes have different prices, and mature processes are the main ones.

Pure water application industries: Different industries have different water quality requirements for pure water, and the application scenarios need to be confirmed with customers.

Equipment installation environment conditions: water inlet and outlet channels and distribution at the construction site, power supply arrangement, actual installation site size, etc.

Based on the raw water quality conditions, pure water effluent quality, effluent water volume, process requirements, industry application scenarios, site conditions, special needs, etc. provided by the customer, a pure water design plan is designed.

- according to the customer’s needs and basic conditions, to determine the program design process.

- according to the process flow, determine the equipment configuration list. Reference case

- Specifications for usage training and daily maintenance: please refer to the specific equipment instruction manual and corporate training.

Customer case

Customer case: electronics industry

The basic needs and circumstances of the client are as follows:

Water in: municipal tap water

Water output: ultra-pure water with resistivity ≥18M ω * cm 25 ° C, water output of 2T/h

Process: negotiate the adoption of mature RO + EDI + mixed bed process

Industry: electronic semiconductor industry

Site: Water Inlet and outlet, power supply, space meet requirements.

According to the customer situation, get the basic design basis:

Raw water quality: local municipal tap water

Design Temperature: 5 ~ 40 °C

Raw water flow: ≥6t/h

Inlet pressure: 0.3-0.6 mpa

Water yield: ≥2T/h

Reverse osmosis system recovery: ≥65%

Water production requirements: resistivity ≥18 m ω * cm 25 ° C

Control mode: full automatic control

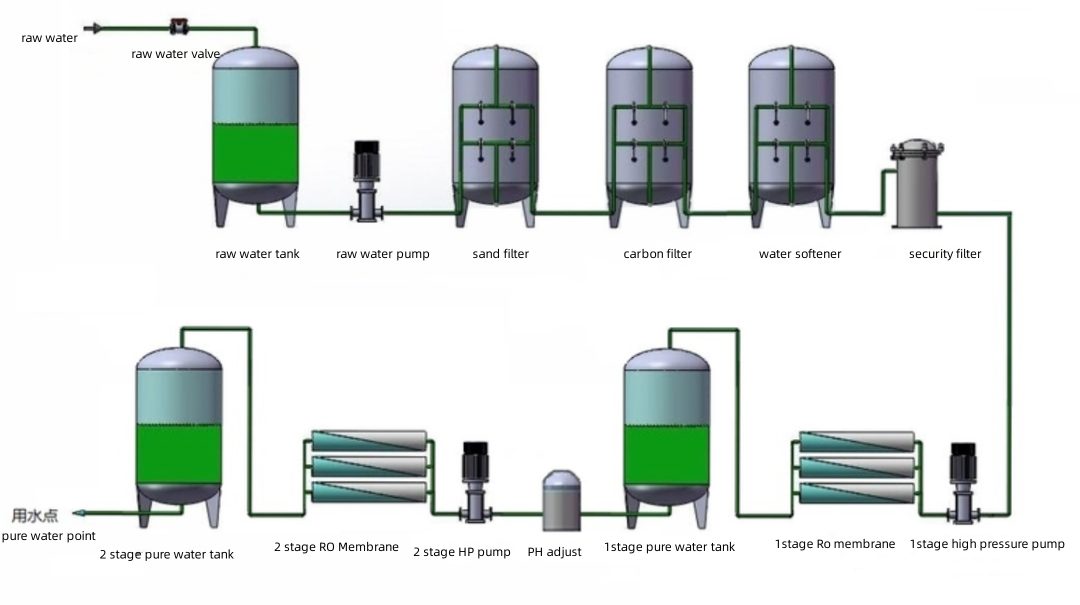

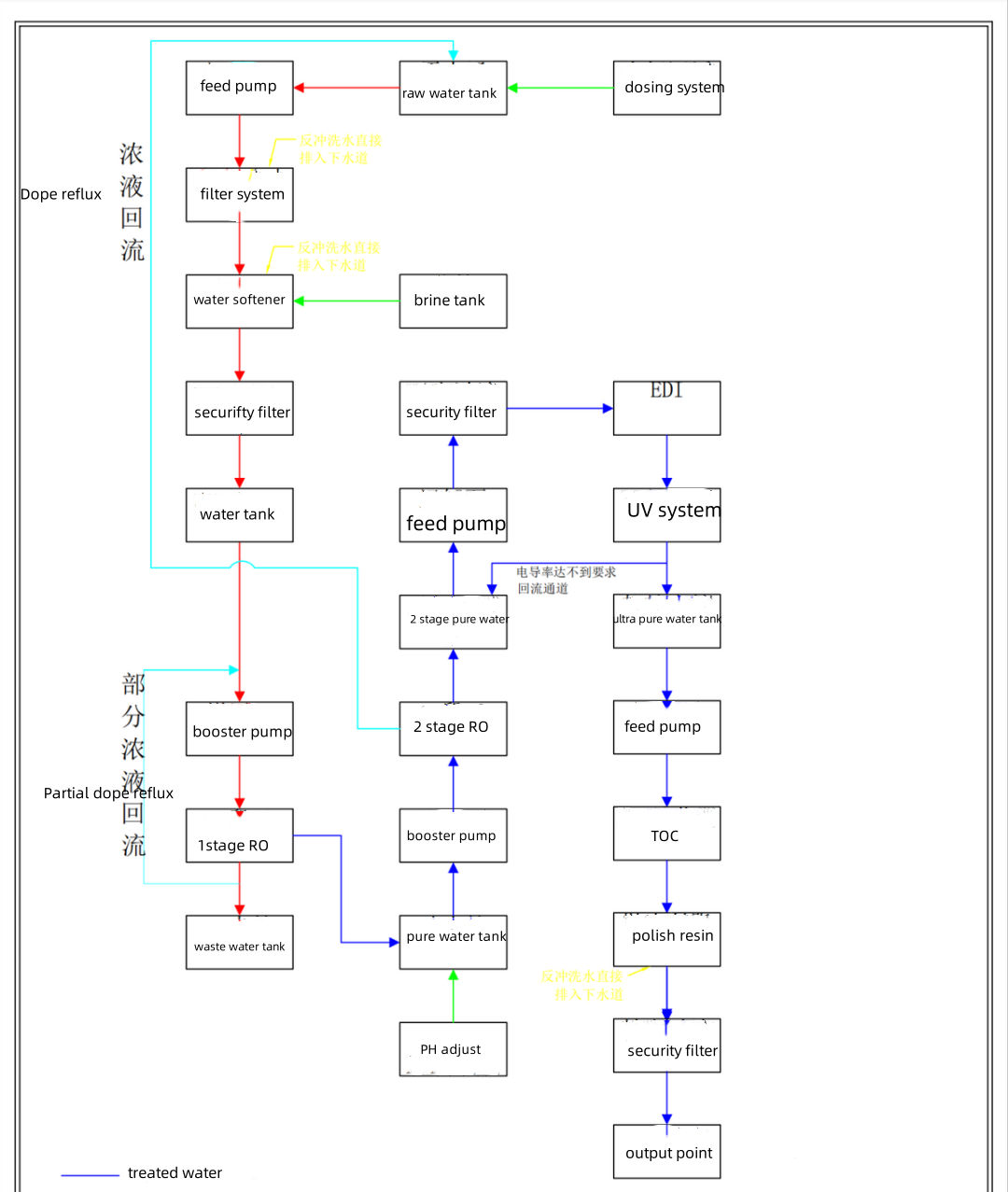

According to the customer, the design process is as follows:

Residual chlorine reduction-raw water tank-conveyor pump-multi-media filter-softener-security filter (5 μm)-transfer water tank (scale inhibitor)-booster pump-first stage ro-first stage pure water tank (PH regulation)-booster pump-second stage ro-second stage pure water tank-conveyor pump-precision filter (5 μm)-ediuv sterilizer-ultra-pure water tank-conveyor pump-toc sterilizer-polishing resin-precision filter (0.22 μm)-use point

According to the process flow, determine the equipment configuration list as follows:

| 2T/H Ultra Pure Water Design Specification | ||||

| NO# | Item | Details | QTY | Unit |

| 一 | Raw water tank | 2000L | 1 | pcs |

| 1 | SOLENOID Valve | DN40 | 1 | pcs |

| 2 | pipe | DN32 | 1 | set |

| 3 | dosing tank | 100L | 1 | pcs |

| 4 | dosing pump | 0-12L/H | 1 | set |

| 5 | water sensor | float | 1 | set |

| 6 | water sensor | float | 1 | set |

| 二 | Booster pump | CHL8-4 | 1 | set |

| 1 | High voltage protection controller | P6A | 1 | set |

| 2 | pressure gauge | 0-0.7 | 1 | pcs |

| 3 | pipe | DN32 | 1 | set |

| 4 | converter | 1.5KW | 1 | set |

| 三 | Filter FRP Tank | 2475 | 1 | pcs |

| 1 | Control Box | F67B | 1 | set |

| 2 | center | 1 | pcs | |

| 3 | top and bottom distributor | 1 | set | |

| 4 | quartz sand | 5-25目 | 1 | set |

| 5 | carbon | 5-15目 | 1 | set |

| 6 | pipe | DN32 | 1 | set |

| 四 | Softener FRP Tank | 2475 | 1 | pcs |

| 1 | Control Box | F63C | 1 | set |

| 2 | center | 1 | pcs | |

| 3 | top and bottom distributor | 1 | set | |

| 4 | resin | 001*7 | 1 | set |

| 5 | pipe | DN32 | 1 | set |

| 6 | brine tank | 100L | 1 | pcs |

| 五 | Security filter | 20inch-5element | 1 | pcs |

| 1 | Connect tee | PE | 1 | pcs |

| 2 | Vent | 1 | pcs | |

| 3 | Pressure gauge connector | PE | 1 | pcs |

| 4 | PP filter | 5μm | 5 | pcs |

| 六 | 1 Stage RO System | |||

| 1 | Water shortage pressure protection switch | P6A | 1 | set |

| 2 | 1 stage booster pump | CDL8-10 | 1 | set |

| converter | 3KW | 1 | set | |

| 3 | return valve | DN32 | 1 | set |

| 4 | High voltage protection controller | P30A | 1 | set |

| 5 | membrane housing | Feb-40 | 2 | pcs |

| 8 | 1 stage RO membrane | 8040 | 3 | pcs |

| 9 | pressure gauge | 0-2.5Mpa | 2 | pcs |

| 10 | wastewater adjust valve | DN20 | 1 | pcs |

| 11 | wastewater flow meter | 0-20 | 1 | pcs |

| 12 | pure water flow meter | 0-20 | 1 | pcs |

| 13 | 1 stage flush valve | DN20 | 1 | pcs |

| 14 | pipe | DN15-DN32 | 1 | set |

| 七 | 1 Stage RO System Pure water Tank | 1000LPH | ||

| 1 | 1 stage water sensor | float | 1 | set |

| 2 | PH dosing system | 0-14 | 1 | set |

| 3 | 2 stage water sensor | float | 1 | set |

| 八 | 2 Stage RO System | |||

| 1 | booster pump 2 stage | CDL8-10 | 1 | set |

| converter | 3KW | 1 | set | |

| 2 | return valve | DN15 | 1 | set |

| 3 | High voltage protection controller | P30A | 1 | set |

| 4 | membrane housing | Feb-40 | 1 | pcs |

| 5 | RO Membrane 2stage | 8040 | 2 | pcs |

| pressure gauge | 0-2.5Mpa | 2 | pcs | |

| 6 | waste water adjust valve | DN20 | 1 | pcs |

| 7 | waste water flow meter | 0-20 | 1 | pcs |

| 8 | pure water flow meter | 0-20 | 1 | pcs |

| 9 | 2 stage flush valve | DN20 | 1 | pcs |

| 10 | pipe | DN15-DN32 | 1 | set |

| 九 | 2 Stage Pure water tank | |||

| 1 | 1 stage water sensor | float | 1 | set |

| 2 | 2 stage water sensor | float | 1 | set |

| 十 | EDI System | 2000LPH | 1 | set |

| 1 | EDI Module | 2吨 | 1 | pcs |

| 2 | feed pump | CHL4-5 | 1 | set |

| converter | 1.1KW | 1 | set | |

| 3 | High voltage protection controller | P6A | 1 | set |

| 4 | Securify filter | 20″-5element | 1 | set |

| 5 | EDI flow meter | 2000L | 2 | pcs |

| 6 | EDI flow meter | 40L | 1 | pcs |

| 7 | EDI adjust valve | DN25 | 2 | pcs |

| 8 | EDI adjust valve | DN15 | 1 | pcs |

| 9 | pressure gauge | 0.7MPA | 3 | pcs |

| 10 | EDI pipe | DN15-DN32 | 1 | lots |

| 十一 | Polish Resin | |||

| 1 | polish resin | 1 | lots | |

| 2 | FRP tank | 1254 | 2 | pcs |

| 3 | pipe | DN15-DN32 | 1 | lots |

| 4 | head | DN25 | 1 | set |

| 十二 | Ultra pure water Tank | Resistivity≥15MΩ*cm | ||

| 1 | float sensor for 1stage | float | 1 | set |

| 2 | float sensor for 2 stage | float | 1 | set |

| 十三 | Circulating piping system | |||

| 1 | feed pump | CHL4-5 | 1 | set |

| converter | 1.1KW | 1 | set | |

| 2 | UV system | 1 | set | |

| 3 | 0.22 securify filter | 0.22μm | 1 | set |

| 4 | TOC sterilizer | 1 | set | |

| 5 | Pipe | DN15-DN32 | 1 | set |

| 十四 | Control Panel | |||

| 1 | Conductivity Meter | CM-230 | 2 | pcs |

| 2 | Resistivity Meter | CM-220 | 2 | pcs |

| 3 | Control Box | 500*500*230 | 1 | pcs |

| 4 | internal electrical components | Schneider, Omron and the same | 1 | set |

| 5 | Touch screen | 7inch | 1 | pcs |

| 6 | PLC | 1 | pcs | |

| 7 | Automation control programming | 1 | set | |

Introduction of main parts of plant

- Raw water tank

As the inlet pressure is not very stable, will cause flow rate instability and affect the filtering effect, and in order to avoid the impact on the preprocessor, it is necessary to configure the original water tank to buffer, balance the water pressure. Equipped with a set of level control valves, one group to high water level, notify the intake solenoid valve closed to prevent water overflow, to low water level when the intake electric valve to open fill water; the other group when the low water level, notice the original pump to stop working, to prevent the original pump dry and idling, re-make water to high water level, the original pump can be re-started to avoid its frequent action. Raw water flow calculation: raw water flow = 2 times of primary RO flow = 3 times of secondary RO/EDI/terminal water output. The original water tank design water tank is approximately equal to the first RO outlet or the terminal outlet.

- Raw water pump

It is mainly used to overcome the resistance of the preprocessor during operation and to provide sufficient water flow for backwashing of the preprocessor. The low level valve through the raw water tank can prevent water shortage and idling. Delivery pumps generally use horizontal multi-stage centrifugal pumps CHL (non-corrosive liquids) CHLF (mildly corrosive liquids) , model reference pump supplier 3 kg pressure (head H = 30m) to reach the delivery capacity (m3/h flow rate per hour) model.

- Reverse osmosis membrane water intake requirements (the main role of pre-treatment)

SDI (silt density index) < 5

Turbidity < 1 NTU

Temperature < 45 °C

Fe, Mn <0.1mg/L

SDI determination method: (SDI refers to the weight of sediment that has been filtered on 0.45 μm membrane for 15 minutes. According to the membrane design manual, this value must be less than 5.) . The water samples were filtered with a microporous membrane with a diameter of 47 mm and an average pore size of 0.45 μm under the pressure of 0.21 MPA. The time t 0 for the initial filtration of 500 ml of water samples was recorded, and after 15 minutes of further filtration, the water samples were filtered with a microporous membrane with a diameter of 47 mm and an average pore size of 0.45 μm, the time of filtering 500ML water sample was recorded again (T15) . Calculate SDI using the following:

SDI=(1- t0/ t15) x 100/15

During the above determination process, the particles, colloids and bacteria larger than 0.45 μm in the water were mostly trapped on the membrane surface, which resulted in the decrease of the permeation rate of the membrane and the prolongation of the time required for filtering the same volume of water samples, so T 0/t 15 < 1. The more suspended matter and colloid matter in the water, the smaller the T 0/t 15 value and the larger the SDI (its limit value is 6.7) .

- Multi-media filters

Multi-media filter is a process of using one or more kinds of filter media to pass high turbidity water through granular or non-granular material under certain pressure, so as to effectively remove suspended impurities and make water clear. The porous material used for filtering is called filter material. Quartz sand is the most common filter material. Commonly used filter media are quartz sand, anthracite, activated carbon, magnetite, Garnet, porous ceramics, plastic balls and so on.

Multi-media filter mainly by the filter body, supporting pipelines and valves. The filter body mainly comprises the following components: a cylinder; a water distribution component; a support component; a backwash gas pipe; a filter material; an exhaust valve (external) , etc. .

The multi-media filter in this system is mainly anthracite (carbon) + quartz sand. The principles of filtration and backwashing refer to separate quartz sand and activated carbon filters. Filter media replacement cycle 1-2 years.

Tank size design: multi-media filter, quartz sand filter, activated carbon filter, water softener.

Filter tank calculation: πr ^ 2 * V (filter speed 15-20m/h) = flow rate (t/h) , extrapolating the tank size and model by flow rate, or selecting the tank directly according to the supplier’s data.

According to the calculated radius of the tank to select the appropriate model. According to this scheme, the flow rate of ultrapure water is 2t/h, the flow rate of primary RO is 3t/h, and the flow rate of pretreatment is about 6T/h.

According to the above formula, the radius is 0.325 m according to the filtration rate of 18M/h. The selected model tank 2475(Φ600 * 1900 mm) has a bottom edge diameter of 24 inches = 609.6 mm (1 inch = 25.4 mm) and a tank height of 1,905 mm.

According to the tank size (fill 2/3 volume) , calculate the amount of materials used.

Dosage = πr ^ 2 * 2/3h * material coefficient, quartz sand * 1(dense) , activated carbon * 0.6(Fluffy) , resin * 0.8(general) , quartz sand 50KG/package, resin 20KG/25L/package, activated carbon 25KG/package.

Quartz sand dosage = 3.14 * 0.3 * 0.3 * 2/3.1.9 * 1 * 1000/50 = 7.2(8 packets)

Active carbon dosage = 3.14 * 0.3 * 0.3 * 2/3.1.9 * 0.6 * 1000/25 = 8.6(9 packets)

Resin dosage = 3.14 * 0.3 * 0.3 * 2/3.1.9 * 0.8 * 1000/20 = 14.3.15 packets, 358L)

4.1 quartz sand filter

The filter material of quartz sand filter is refined quartz sand. The upper part of the filter layer is lighter quartz sand with smaller particle size, and the lower part is larger quartz sand, this can give full play to the efficiency of the entire filter layer, improve the ability to intercept pollution. The Mechanical filter is mainly used to remove particles, colloids, suspended solids, turbidity, etc. . The turbidity of the effluent is less than 1 NTU with SDI ≤5. Can be carried out through the control valve positive and negative washing, in order to flush off the surface of the dirt, to prevent its clogging, to restore its filtering capacity.

Filter

When the system is in a filtering state, the unfiltered water passes through the water distributor to reach the packing layer in the filter in a near advection state. When water flows through the packing layer, impurities are trapped in the packing layer. A filter collector is arranged at the bottom of the filter, and the filtered water is uniformly collected and discharged. Horizontal flow filter, determine the filter can be filtered at high flow rate, still can achieve better filtering effect.

Anti-washing

With the accumulation of impurities in the packing layer, the pressure head loss will increase. When the pressure head loss reaches a certain set limit (when the filter inlet and outlet pressure difference is increased by 0.07 MPA compared with the initial operation) , the system is converted to a backwash state to clean the accumulated impurities, avoid long-term operation of quartz sand and plate caking. To enhance the effect of backwashing, a Compressed air can be provided during backwashing.

Filter material replacement

When the turbidity of the effluent is more than 1 NTU, it is necessary to find out the cause and see if the packing needs to be changed. As the case may be, under the condition of continuous operation, the packing is generally changed once every two years or so.

Features

The invention can effectively remove colloid and suspended matter in raw water;

The unique uniform water distribution method can prevent and retain the filter media to balance the resistance of the filter layer to prevent bias, so as to achieve the best effect of the filter;

* choose high-quality filter media, filter media non-uniformity coefficient of 2-3 to ensure a good filtering effect, and will not appear anti-clutter layer phenomenon;

* a lower operating flow rate is chosen to accommodate the possibility of deterioration of water quality in the future;

4.2 activated carbon filters

As the reverse osmosis membrane is very sensitive to residual chlorine, organic matter, so must be equipped with activated carbon adsorption residual chlorine, organic matter, to meet the reverse osmosis membrane water requirements. Activated carbon has a very strong adsorption and filtration performance, on the water of residual chlorine, color, smell, organic matter, microorganisms, etc. have a very strong adsorption.

After activated carbon filter treatment, the water quality can reach the following indexes: CODMn ≤2ppm, residual chlorine < 0.1 ppm.

Adsorption principle

An equilibrium surface concentration is formed on the surface of the activated carbon particles, and then the organic impurities are adsorbed into the activated carbon particles. But over time, the adsorption capacity of activated carbon will be reduced to varying degrees, the adsorption effect will also decline. Therefore, activated carbon should be regularly clean, regeneration or replacement.

Principle of residual chlorine removal

The oxygen-containing functional groups in the porous portion of the activated carbon react rapidly with the oxidizing hypochlorite in the water to remove the oxidizing hypochlorite.

Filter

When the system is in a filtering state, the unfiltered water passes through the water distributor to reach the packing layer in the filter in a near advection state. When water flows through the packing layer, impurities are trapped in the packing layer. A filter collector is arranged at the bottom of the filter, and the filtered water is uniformly collected and discharged. Horizontal flow filter, determine the filter can be filtered at high flow rate, still can achieve better filtering effect.

Anti-washing

With the accumulation of impurities in the packing layer, the pressure head loss will increase. When the pressure head loss reaches a certain set limit, the system will be converted to the backwash state, in order to clean the accumulated impurities.

Replacement of fillers

Because the backwashing of the activated carbon filter can only wash off the pollutants on the surface of the activated carbon, and it is impossible to wash off a large number of pollutants adsorbed in the pores of the carbon particles. Therefore, when activated carbon is saturated and the free residual chlorine in effluent is more than 0.1 ppm, the replacement of activated carbon should be considered, and the replacement period of activated carbon is suggested to be one year.

Features

* can effectively remove the residual chlorine, color, odor, organic matter, microorganisms in raw water this index to explain specific; (activated carbon specific surface area, iodine adsorption capacity of 900-1100 mg/g)

The unique uniform water distribution method can prevent and retain the filter media to balance the resistance of the filter layer to prevent bias, so as to achieve the best effect of the filter;

* choose high-quality filter media, filter media non-uniformity coefficient of 2-3 to ensure a good filtering effect, and will not appear anti-clutter layer phenomenon;

* choose a lower operating flow rate to accommodate the possibility of deterioration of water quality in the future.

- Softeners

Natural water contains a variety of salts, these salts dissolved in the water to form ionic substances. That is, anions and cations, ionic substances in water in the process of heating or contact with other solutes (such as detergent) will be combined into insoluble substances in water, usually in water, calcium, magnesium plasma will form scale, it brings a lot of inconvenience and harm to the production and daily life, and it will cause RO membrane scaling in the reverse osmosis system.

As its name suggests, softening reduces the hardness of water. Since the hardness of water is mainly formed and expressed by calcium and magnesium, positive Ion-exchange resin are used to replace the CA 2 + and MG 2 + (the main components of scale formation) in water, with the increase of Ca2 + and Mg2 + in the resin, the function of removing Ca2 + and Mg2 + in the resin decreases gradually. Therefore, when the softening water equipment is used for a period of time, the resin needs to be regenerated with the salt regeneration part to restore the efficiency of the resin, improve the service life of the resin.

When the raw water passes through the sodium Ion-exchange resin, the Ca2 + and Mg2 + ions in the water exchange with the NA2 + ions in the resin, which reduces the hardness of the water and softens the water quality. By exchanging the sodium ions in the Ion-exchange resin with the calcium and magnesium ions in the water, the hardness of the water is reduced, and the concentration of calcium and magnesium ions in the water is reduced, so as to meet the requirements of chemical and boiler production of water hardness standards.

The outlet hardness was less than 0.03 mmol/L and the working pressure was 0.3-0.6 mpa.

- Security filter (one type of precision filter, precision 5 μm)

In order to ensure that the reverse osmosis membrane elements are not injured by suspended particles, the system sets up security filter, filter precision is 5μm, built-in polypropylene filter (melt-blown PP) , the shell is stainless steel structure. When the pressure difference between the inlet and outlet of the filter reaches 0.75 mpa, it is necessary to change the inner filter element of the filter. Under normal working conditions, the filter element can maintain more than 3-6 months of service life.

Note: both security filter and microporous filter are precision filters. Precision filter if used in reverse osmosis front, it is called security filter, security filter is to ensure the safety of water into the membrane, the general accuracy of 5 microns. If used behind reverse osmosis or ultra-shallow membranes, precision filters are also known as microporous membrane filters, where the filter accuracy is usually less than 1 micron (commonly used 0.1/0.22 μm) , the utility model mainly removes impurities in the water after the bacteria in the water are intercepted by the ultraviolet ray sterilizer.

- Booster pumps

Raise the RO inlet pressure to meet the RO operation needs of the inlet pressure and flow. High pressure pump inlet pressure switch, low pressure alarm and stop the pump. Water outlet equipped with high-pressure switch, high-pressure alarm and stop pumping. Booster pump generally choose vertical multi-stage centrifugal pump CDL (non-corrosive liquid)/CDLF (mild corrosive liquid) , model reference pump supplier 10 kg pressure (head H = 100m) can reach the delivery capacity (per hour flow M3/h) model.

- Reverse osmosis plant(primary RO and secondary RO)

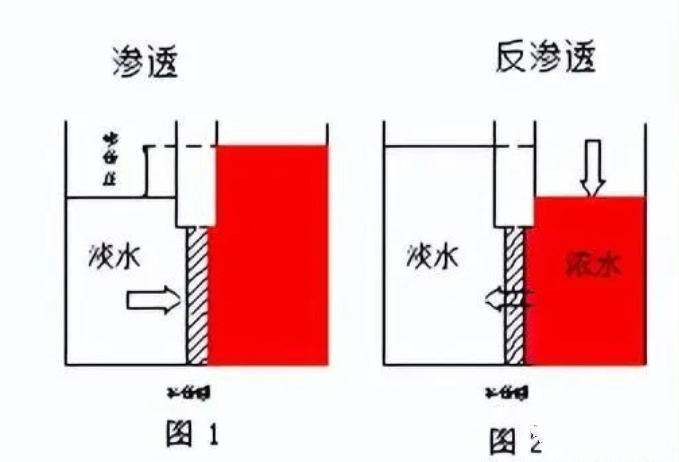

The pure water is separated from the solution containing the solute by a semi-permeable membrane which can only pass through water. At this time, the water on the pure water side spontaneously passes through the semi-permeable membrane and enters one side of the solution. The water surface on the solution side rises, this phenomenon is called Reverse Osmosis. When the liquid level rises to a certain height, the pressure on both sides of the membrane reaches equilibrium and the liquid level on the solution side does not rise any more. If a pressure greater than the osmotic pressure is applied to the side of the solution, the water molecules in the solution will be squeezed to the side of the pure water. We can see from the reverse osmosis process, due to the effect of pressure, the water molecules in the solution into pure water, pure water increased, and the solution itself is concentrated.

When the raw water is sent to the reverse osmosis membrane at a certain pressure, the water penetrates the tiny pore size on the membrane, and after collection, the pure water is obtained, the impurities in water, such as soluble solids, organic matter, colloidal substances and bacteria, are trapped by reverse osmosis membrane, concentrated in the intercepting fluid and removed. First-order reverse osmosis can remove more than 97% of the dissolved solids in raw water, more than 99% of organic matter and colloid, almost 100% of bacteria.

RO system is one of the most advanced equipment to produce pure water in the water treatment plant in the world. It is the first choice of the users for its low cost, economy, convenient operation and reliable operation.

The capacity of the equipment is the value of the raw water at 25 ° C, the standard production condition. Before and after each water-making and operation will be automatic large flow membrane, can extend its service life.

The design flux of reverse osmosis membrane element is not larger than the maximum flux value specified in the guideline of membrane element manufacturer.

Feed water dosing type and dosing point of reverse osmosis device, the choice of chemical cleaning fluid according to feed water quality and selected reverse osmosis device characteristics of membrane components determined. Party B puts forward the types and requirements of the required drugs.

The feed water and concentrated water inlet and outlet main pipes of each section of reverse osmosis device are provided with enough connections and valves, so as to be connected with the inlet and outlet pipes of cleaning fluid during cleaning.

Reverse osmosis concentrated water drainage installed flow control valve to control the recovery rate of water.

The reverse osmosis device is controlled by automatic program, and the reverse osmosis membrane is rinsed automatically by time-delay program.

The number and location of sampling points can effectively diagnose and determine the operation status of the system.

The reverse osmosis membrane module is installed on the assembly rack, which is equipped with all pipes and joints, including all brackets, fasteners, fixtures and other accessories.

The design of reverse osmosis combined frame meets the seismic intensity requirements of its site and the expansion requirements of components.

The measuring collocation and quantity of reverse osmosis system meet the needs of safe, stable and reliable operation of the system. The instrument adopts the instrument panel centralized arrangement.

Pressure indicator tables are installed at the inlet of each section of reverse osmosis, drainage of first section and outlet of concentrated water.

Reverse osmosis total product water and concentrated water drainage installed flow meter.

Reverse osmosis product water pipes are equipped with an on-line conductivity meter showing water quality.

In this scheme, the first RO is arranged at 2∶1, the designed water yield is 3 m 3/h, the recovery rate is about 75% , and the second RO is arranged at 1∶1, the membrane is arranged in series, the designed water yield is 2m3/h and the recovery rate is about 80% . Multi-stage and multi-stage reverse osmosis model of the future separate introduction.

- Ro pure water tank

Used to store reverse osmosis pure water. Equipped with a set of level control valve, when the tank level reached the high level signal, notify the first reverse osmosis device to stop working, to prevent water overflow, when the tank level below the level control valve, reverse osmosis device on the automatic start to recharge water. At the same time play a role in stabilizing water pressure for back-end equipment.

- EDI booster pump

The water from the secondary RO tank is pumped to the follow-up treatment plant to provide the pressure and flow needed to meet the normal operation of the follow-up equipment. The water pump is controlled by the water tank level chain, when the water tank is in the low level, the water pump stops running, to avoid the water pump in the state of operation caused by damage. General selection of horizontal multi-stage centrifugal pump CHL (non-corrosive liquid) , model reference pump suppliers slightly more than 3, not more than 5 kg pressure, can reach the delivery capacity (m3/h flow rate per hour) of the model.

- Precision filter (5 μm)

Installed in front of the water inlet of EDI device, it is used to intercept the small particle impurities that may exist in the supply water and protect the stable operation of EDI module.

- EDI System

It is usually used in reverse osmosis systems to replace the traditional mixed ion exchange technology (MB-DI) for the production of stable deionized water.

EDI technology has the following advantages over mixed ion exchange technology:

The concentrated water chamber uses a patented resin filling technology that eliminates the need for circulating pumps and saline injection;

Simple system, easy operation;

High reliability;

Good electrical insulation;

100 PSI (7 bar) , continuous operation at 45 ° C;

Low-cost operation effect is obvious;

Double”O” ring seal, ensure no leakage operation;

An EDI unit is formed by filling a Ion-exchange resin between anions and cations exchange membranes. In the EDI module, a certain number of EDI units are separated by a mesh to form a concentrated freshwater chamber. A negative/positive electrode is arranged at both ends of the unit group. Driven by direct current, the anion and cation in the fresh water chamber flow respectively pass through the anion and cation exchange membrane into the concentrated water chamber and are removed in the fresh water chamber.

EDI system generally reverse osmosis (RO) pure water as Edi feed water. The conductivity of RO effluent is 20-1μs/cm (25 ° C) . The outlet water resistivity of EDI can be as high as 18 m ω * cm (25 ° C) . The outlet water resistivity of EDI is more than 17 m ω * cm at the beginning of actual operation, and slowly decreases to more than 15 m ω * cm at the later stage. According to deionized water use and system configuration settings, EDI water is suitable for the preparation of pure water with resistivity requirements of 5-18.2 m ω * cm (25 ° C) . EDI technology is widely accepted by pharmaceutical industry, microelectronics industry, power generation industry and laboratories. It is widely used in surface cleaning, surface coating, electrolysis industry and chemical industry.

EDI influent quality requirements:

| Conductivity40-2μS/cm(25℃) | PH: 5-9 | inlet presure 1.4~7Bar |

| total hardness <1.0 mg/L as CaCO3 | silicon <0.5 mg/L | temp:4 ~45℃ |

According to the water demand of the user and the water balance of the whole water system, the EDI electric desalination unit is designed with a capacity of 2.0 m3/h. The EDI device is equipped with enough on-line instruments and chemical instruments, including pressure gauge, flowmeter, conductivity, resistivity, etc. . The EDI membrane reactor is made by mcness. The resistivity of water production is stable, and the recovery rate is over 90% .

- Ultra-pure water tanks

For storage of EDI water, resistivity ≥15M ω * cm. Water tank distribution level controller; automatically start the EDI booster pump when the water level is low; automatically stop the EDI booster pump when the water level is high; at the same time with the ultra-pure pump linkage, automatically lock the water tank when the water level is low, ultra pure water pump can not start.

- Ultra pure water pump

The pure water in the ultra-pure water tank provides the water supply pressure and flow rate required for the stable operation of the terminal treatment equipment. In order to avoid the fluctuation of water pressure and flow on the impact of water quality.

- Microporous membrane filter (one kind of precision filter, 0.1/0.22 μm is usually selected)

It is mainly to remove the impurities of bacteria in the water after passing through the ultraviolet sterilizer (UV sterilizer and TOC sterilizer) , and can also intercept the mixed-bed resin that falls off improperly.

- Use points

Ultra-pure water with a resistivity of more than 18 m ω * cm is very easy to contact the air and reduce the resistivity, so it is usually prepared for immediate use in a way that pipes are directly connected to the point of use without additional ultra-pure water tanks.

The System technical specification parameter summary:

| NO# | Project | Details |

| 1 | Name | water treatment system |

| 2 | pure water purpose | Ultrapure water for industrial use |

| 3 | pure water quality | Product water conductivity≤0.056us/cm 25℃,Resistivity≥18MΩ*cm 25℃ |

| 4 | output capacity | ≥2.0T/H |

| 5 | raw water | tap water,capacity≥6.0T/H,inlet pureesure:0.3-0.6MPa |

| 6 | power | 220V&380V,50Hz |