Seawater desalination is a technology and process for obtaining freshwater from seawater, which is of great significance for water-scarce regions. Currently, there are two main methods for large-scale seawater desalination: distillation and reverse osmosis. This article will focus on the process of reverse osmosis seawater desalination.

September 18, 2024

Reverse Osmosis Seawater Desalination Process

The main process steps of reverse osmosis seawater desalination include:

Seawater Intake and Pretreatment

1. Seawater Intake: Dig wells or build intake facilities on the seashore to introduce seawater into the pretreatment system.

2. Disinfection and Algae Removal: Add chemical agents such as liquid chlorine, sodium hypochlorite, or copper sulfate to the intake seawater to eliminate microorganisms, bacteria, and algae. This step prevents biological contamination from affecting the normal operation of subsequent equipment and pipelines.

3. Coagulation and Sedimentation: Add coagulants to make suspended solids and colloidal particles in seawater aggregate into larger particles and settle down.

4. Multi-media Filtration: The seawater after coagulation and sedimentation passes through multi-media filters to further remove small suspended solids and particles, improving water quality.

5. Heating and Temperature Adjustment: Heat the pretreated seawater to 20°C-30°C to improve reverse osmosis efficiency.

Chemical Treatment

- Scale Inhibitor Addition: Due to the high hardness and alkalinity of seawater, it is prone to scaling in equipment. Adding scale inhibitors can prevent scaling and ensure long-term stable operation of the system.

- Reducing Agent Addition: Since oxidants were added during the disinfection process, reducing agents need to be added before entering the reverse osmosis system to reduce the residual chlorine content to below 0.1ppm (or ORP<200mV) to protect the reverse osmosis membranes.

Security Filtration

8. Security Filtration: Use security filters made of 316L stainless steel with a filter cartridge pore size of typically 5μm to filter out particulate impurities larger than 5μm in diameter, protecting subsequent high-pressure pumps, energy recovery devices, and reverse osmosis membrane elements

High-Pressure Pump and Energy Recovery

9. High-Pressure Pump Pressurization: Use high-pressure pumps to pressurize the pretreated seawater to 5-7MPa, providing the required pressure for the reverse osmosis process.

10. Energy Recovery: Employ energy recovery devices such as hydraulic turbines to utilize the pressure of the concentrated seawater discharged from reverse osmosis, increasing inlet water pressure by about 30%, reducing energy consumption and operating cos

Reverse Osmosis Process

- Reverse Osmosis Separation: Pressurized seawater enters the reverse osmosis unit, where water molecules are separated from salt molecules through semi-permeable membranes. Pure water passes through the membrane as product water, while concentrated seawater is discharged from the other side.

- Reverse Osmosis Membrane Elements: Select high-performance reverse osmosis membranes suitable for seawater desalination, featuring high salt rejection, pressure resistance, oxidation resistance, and fouling resistance.

Product Water Treatment

- pH Adjustment: Adjust the pH value of the reverse osmosis product water to make it suitable for specific uses.

- Mineralization: If needed, perform mineralization treatment on the product water to adjust water quality.

System Control and Monitoring

15. Automation Control: Use programmable logic controllers (PLC) to build a control system with distributed sampling and centralized monitoring.

16. Parameter Monitoring: Real-time monitoring of system pressure, flow rate, conductivity, and other parameters, with high and low-pressure protection switches and automatic switching devices.

17. Variable Frequency Control: Apply variable frequency control to high-pressure pumps, achieving soft start and soft stop, saving energy, and protecting equipment.

18. Automatic Flushing: Perform low-pressure automatic flushing before and after startup and shutdown to displace concentrated seawater and protect membrane surfaces from contamination.

19. Data Management: Display, store, analyze, and print system parameters such as temperature, flow rate, water quality, and water production.

Advantages and Disadvantages of Reverse Osmosis Seawater Desalination

Advantages

- Low Energy Consumption: The reverse osmosis process involves no phase change, with electricity consumption of only 3.0-5.5kWh per ton of water.

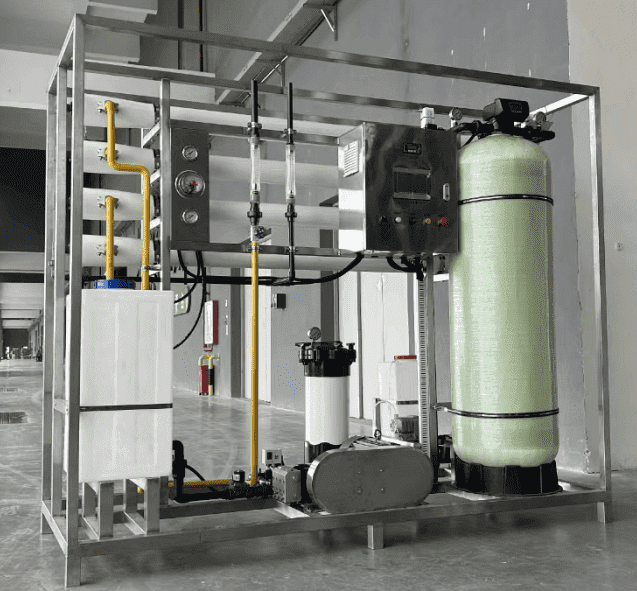

- Compact Equipment: The installation has a small footprint, suitable for applications of various scales.

- Easy Operation: System operation and maintenance are relatively simple.

- High Adaptability: Water production scale can be flexibly adjusted according to demand.

Disadvantages

- High Membrane Cost: The cost of reverse osmosis membrane materials is relatively high, affecting operating costs.

- Strict Pretreatment Requirements: High requirements for inlet water quality necessitate complex pretreatment processes.

- Product Water Quality: The salt content of product water is generally above 50mg/L, lower than that of distillation methods.

- Membrane Fouling and Scaling: Reverse osmosis membranes are prone to fouling and scaling, requiring regular cleaning and replacement.

Reverse osmosis seawater desalination technology has become one of the mainstream technologies for seawater desalination due to its low energy consumption and compact equipment. With continuous advancements in membrane material technology and improvements in pretreatment processes, the efficiency and economic viability of reverse osmosis seawater desalination will further improve. However, in application, attention must still be paid to the importance of pretreatment and the prevention and control of membrane fouling and scaling issues to ensure long-term stable operation of the system.

In the future, the development of seawater desalination technology will move towards more efficient, environmentally friendly, and economical directions. Combined with new technologies such as renewable energy and intelligent control, seawater desalination will make greater contributions to alleviating global water shortage problems.

How to Choose the Right Pure Water Treatment Equipment for Your Needs?

November 10, 2025

How to Choose the Right Pure Water Treatment Equipment for Your Needs? (by ROAGUA – Professional Water Treatment Equipment Manufacturer, China)

Turn Muddy Water into Clean Water: ROAGUA Stainless Steel Ultrafiltration Water Purifier for Africa

November 5, 2025

Clean Water for Every Village – ROAGUA Stainless Steel Ultrafiltration Water Purifier Built for Africa’s Tough Water Conditions

How Do You Select the Right 500LPH RO System?

October 14, 2025

buy right 500LPH RO System, please read this one first