December 24, 2021

Ultrafiltration membrane filtration principle

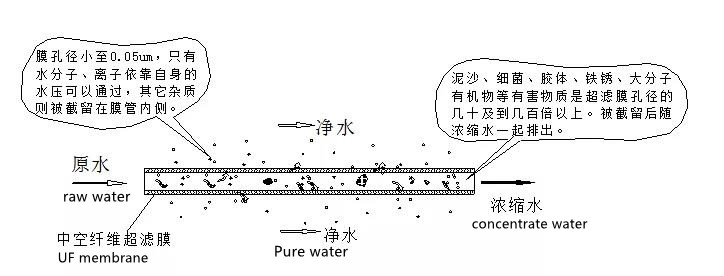

Hollow fiber ultrafiltration membrane is an important branch of membrane separation technology. It is characterized by separation at room temperature and low pressure. It has the advantages of low energy consumption, high filtration accuracy, large water production, and strong anti-fouling ability. It can effectively filter water Bacteria, colloids, suspended solids, rust, macromolecular organic matter and other harmful substances. The principle of hollow fiber ultrafiltration membrane for water purification is shown in Figure 1 below:

Performance characteristics of ultrafiltration system

1. High filtration accuracy, the ultrafiltration filter pore size is in the range of 0.001-0.1m, which can effectively filter out harmful substances such as bacteria, colloids, suspended solids, rust, and macromolecular organics in the water. Significantly reduce COD, SS, SDI and turbidity, etc., to ensure that the effluent is stable and up to standard.

2. If ultrafiltration effluent is used as reverse osmosis inlet water, it can prolong the cleaning cycle of the reverse osmosis membrane and the life of the membrane, and increase the water production.

3. Fully automatic control of system operation.

4. Compact structure and small footprint.

5. Low operating pressure and low operating cost.

6. The operation is simple, safe and easy to maintain.

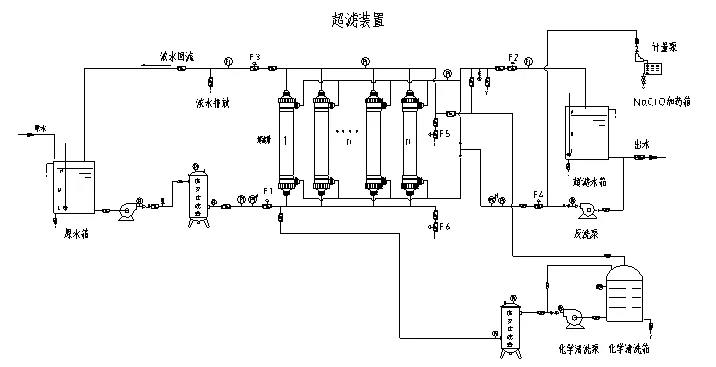

Standard process flow chart

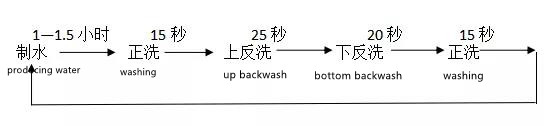

work process:

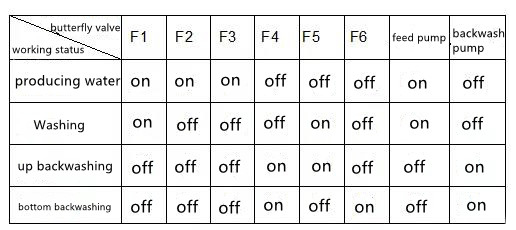

Pneumatic butterfly valve opening state of each working procedure

System operation instructions

1. Connect the ultrafiltration host to the peripheral equipment (water pump, water tank, etc.) according to the process flow chart. A security filter must be installed before the water inlet of the host.

2. After checking the pipeline connection is correct, disconnect all the live connections connected to the ultrafiltration main unit, clean the pipeline connected to the main unit, and rinse with water for 5-10 minutes until it is cleaned. Pay attention to the direct drain of the cleaning water. Do not enter the ultrafiltration, so as not to damage the ultrafiltration membrane by large particles of impurities, and check whether there is any water leakage at each connection of the pipeline.

3. Turn down the inlet valve of the ultrafiltration main unit, open all the water production valve, concentrated water return valve and backwash valve, close the medicine washing water inlet valve and return valve, to avoid excessive water pressure when starting up, causing damage The impact of the ultrafiltration membrane damages the equipment. Then turn the “auto/manual” knob on the electric control box panel to the manual position, open the “ultrafiltration cross-flow valve”, then open the “ultrafiltration inlet valve”, and then slowly open the inlet valve and close it. Cross-flow valve, adjust the inlet water pressure P1 to be less than 0.2Mpa, flush the ultrafiltration membrane for 5-10 minutes, rinse the protective liquid in the ultrafiltration membrane, and check the interface and pipeline for leakage.

4. After the above cleaning is completed, the ultrafiltration system can enter the formal commissioning operation. Open the inlet valve slightly, open the outlet valve and the cross-flow valve, turn the “Auto/Manual” knob to the automatic gear, and adjust the inlet valve. , Cross-flow valve, water production valve, make the pressure of produced water 0.02-0.05Mpa, the flow of produced water is about the design flow, the flow of concentrated water is about 10%-50% of the influent flow according to the turbidity of the raw water. The inlet water pressure is the initial inlet water pressure. When the flow rate of the produced water is guaranteed, the lower the inlet pressure is, the better. The maximum inlet pressure must not exceed 0.3Mpa, and the backwash pressure must not exceed 0.20Mpa.

5. According to the water quality of the raw water, set the backwash cycle. In the range of 60-90 minutes, the worse the water quality, the shorter the cycle. Normal washing is 15 seconds, upper backwash is 25 seconds, and lower backwash is 20 seconds. .

Chemical cleaning

With the long-term use of ultrafiltration membrane modules, when the water production of the ultrafiltration membrane drops by more than 20% or after 1-4 months of use, the ultrafiltration membrane needs to be chemically cleaned in order to remove the pollutants on the ultrafiltration membrane in time , To prevent the ultrafiltration membrane from forming stubborn fouling, chemical cleaning is divided into:

a. Pickling: Use citric acid to adjust the PH value of RO reverse osmosis water (or ultra-filtered water) in the chemical tank to PH=2

b. Alkaline washing: use sodium hydroxide and sodium hypochlorite to adjust the RO reverse osmosis water (or ultra-filtered water) in the chemical tank to PH=12

Note: After acid washing, use alkaline washing again, and finally wash with clean water until the effluent PH=7, otherwise it will affect the water flux.

Chemical cleaning method:

Pour the medicine into the chemical cleaning box according to the amount and prepare the cleaning solution.

Turn on the medicine washing water inlet valve and the reflux valve, turn the “auto/manual” knob on the electric control box panel to manual, start the medicine washing pump, adjust the water inlet valve so that the pressure gauge shows the pressure P=0.20MPa, and the pressure is exceeded. The filter membrane is subjected to positive drug washing. After the positive drug washing for 10 minutes, the product water return valve is opened, and the water production and positive washing are performed for 20 minutes to 60 minutes.

Operation precautions

1. The designed water production volume of the ultrafiltration system is usually measured under the conditions of 25℃ water temperature and standard pressure. If the water temperature rises or falls, the water production also increases or decreases. When the water temperature drops by 1℃, the water production drops by 2.13%. The opposite is true when the temperature rises.

2. The ultrafiltration membrane is best installed indoors to avoid sun and rain.

3. When the ultrafiltration system is working normally, the value of the inlet pressure gauge is 0.1-0.3Mpa, and the pressure cannot be arbitrarily increased to increase the water volume, otherwise the membrane elements will be damaged. The pressure value can be adjusted by the ultrafiltration water inlet butterfly valve.

4. Before starting the machine, please make sure that the valves are in the correct position. The booster pump can be turned on after the inlet valve is closed, otherwise the pressure gauge and ultrafiltration membrane may be damaged. After turning on the raw water pump, adjust the inlet valve to the inlet pressure. It is 0.1-0.3Mpa.

5. When the ultrafiltration membrane is started for the first time, use low-pressure, low-flow inlet water to drive away the air in the membrane module. The inlet pressure should be as low as possible. Water should be fed from the bottom of the membrane to flush all the produced water and concentrated water during the process. It should be discharged; every subsequent start and stop will involve sudden changes in system pressure and flow, impact on membrane modules, etc. Therefore, the number of start and stop of system equipment should be minimized, and the normal start and stop process should also It should be as stable as possible, especially the rise of inlet water pressure and flow rate should be slow;

6. If the ultrafiltration inlet pressure is higher than 0.3Mpa, the inlet water quality fluctuates greatly, or the ultrafiltration produced water quality does not meet the standard, stop the machine and check the reason.

7. When the transmembrane pressure difference of the ultrafiltration membrane Δp≤0.2MPa, the series runs normally, and when the transmembrane pressure difference Δp>0.2Mpa, it means that the membrane is blocked seriously and needs to be shut down for treatment (chemical cleaning).

8. After the system shuts down, follow the following treatments:

1) Prevent the membrane from drying out due to loss of water. After the membrane loses water, there will be an irreversible drop in water production;

2) Use appropriate protective measures to prevent the growth of microorganisms or perform regular flushing every 24 hours;

3) When not in use for a long time (more than 5 days), please fill the ultrafiltration membrane with a protective solution for storage to prevent the loss of water from the ultrafiltration membrane and cause a drop in water production.

The formula in the protection solution: (1% sodium metabisulfite + 10% propylene glycol protection solution + 89% RO reverse osmosis water or ultrafiltration water).

maintenance

1. Regularly clean or replace the filter bag or filter element of the security filter. When the pressure drop of the security filter exceeds 50% of the initial pressure drop, replace the filter bag with a new one.

2. Regular chemical cleaning of the ultrafiltration membrane

1) Timing of cleaning

During the operation of the ultrafiltration system, the colloidal particles, microorganisms, and macromolecular organics in the influent water are carried in the membrane tube. These pollutants are deposited on the membrane surface, resulting in a decrease in the system’s water production and water quality. When the following In this case, chemical cleaning is required to remove contaminants in time and restore membrane performance.

- When the standardized water production drops by more than 20%;

- The standardized transmembrane pressure difference reaches 0.15MPa;

(The above standard comparison conditions are taken from the operating performance of the system after the first 48 hours of operation.)

After the system has been running continuously for 1-4 months, when the water production of the system has dropped by more than 20% of the initial water production or the transmembrane pressure difference has increased by more than 25% of the initial pressure, the ultrafiltration system shall be chemically cleaned.

2) Cleaning method: Refer to 7. Chemical cleaning

Table 1: Comparison table of different pollutants and chemical cleaning formulas:

| Contaminant type | Common pollutants | Chemical cleaning formula |

| Inorganic | Calcium carbonate, iron salt and inorganic colloid | PH=2 citric acid, hydrochloric acid or oxalic acid solution |

| Insoluble inorganic salts such as barium sulfate and calcium sulfate | About 1% EDTA solution | |

| Organic matter | Fat, humic acid, organic colloid, etc. | Sodium hydroxide solution with PH=12 |

| Grease and other difficult-to-clean organic pollutants | 0.1%-0.5% sodium lauryl sulfate, Triton X-100, etc. | |

| Protein, starch, oil, polysaccharide, etc. | 0.5%-1.5% of protease, amylase, etc. | |

| microorganism | Bacteria, viruses, etc. | About 1% hydrogen peroxide or 50ppm sodium hypochlorite solution |

Common faults and troubleshooting of ultrafiltration system

| Failure phenomenon | Cause Analysis | Elimination means |

| Low water pressure or insufficient water supply | Clogged precision filter | Clean or replace the precision filter element |

| Water production has fallen by more than 20% of the initial water production | The ultrafiltration membrane is contaminated | Carry out chemical cleaning and dosing sterilization |

| Transmembrane pressure difference is too small | Increase the inlet water pressure, but not more than 0.2MPA | |

| The interception rate has dropped and the effluent quality has deteriorated | Concentration polarization | Increase the return flow of concentrated water and accelerate the flow velocity in the membrane tube |

| Broken wire | Find out the broken wire and repair it with epoxy resin or replace the ultrafiltration membrane | |

| The pressure of the pressure gauge suddenly rises | Electric valve malfunction | Check that the electric valve is broken or the control circuit is faulty |

| The system does not produce water | Inlet water pressure is too high | Adjust the inlet valve of the ultrafiltration host to make the inlet pressure less than 0.3MPA |

| The water level of the ultrafiltration water tank is too high | Wait for the water level of the production water tank to drop before starting |

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024