October 14, 2022

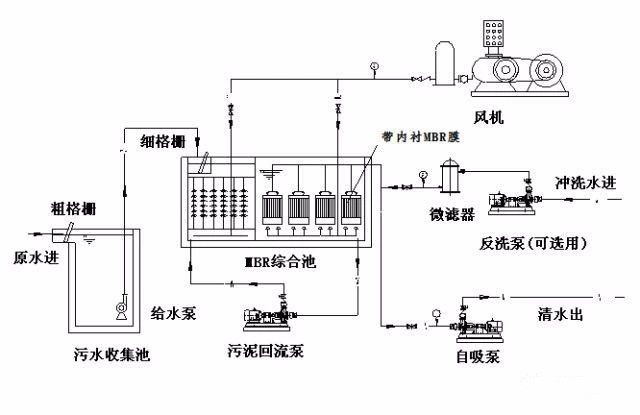

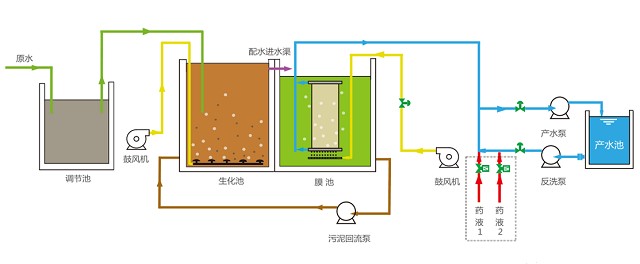

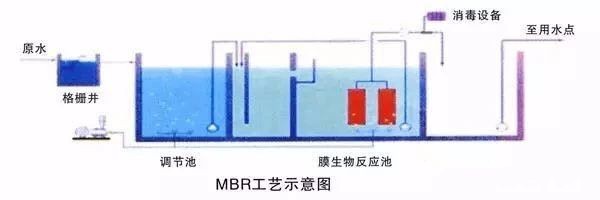

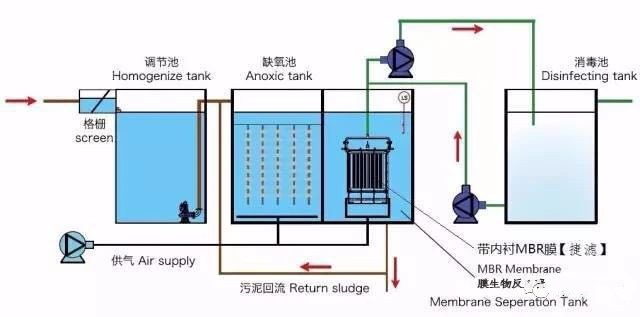

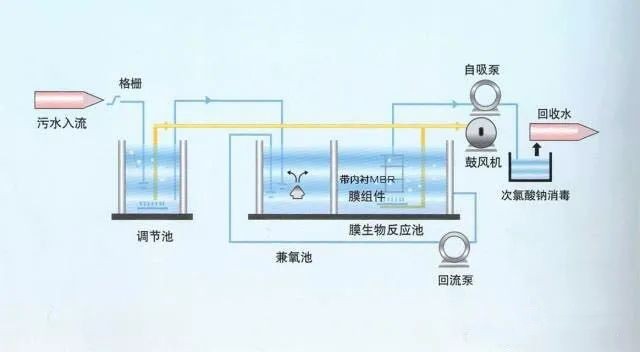

MBR membrane process is an emerging pollution prevention and treatment process in recent years, which is a new type of wastewater treatment mainly applying biological treatment method and bionic membrane separation method.

In the treatment of high-concentration wastewater, the MBR membrane process is much more effective than the physical treatment methods of the past. It has superior performance in the treatment of domestic wastewater, especially in small areas, and has the advantage of a small footprint.

MBR technology is now focused on areas such as water reuse, urban wastewater, industrial wastewater, manure wastewater disposal, and lightly polluted drinking water purification. So what are the advantages and disadvantages of the MBR membrane process?

Advantages of MBR membrane

Separation of hydraulic retention time and sludge age

MBR membrane technology can retain all the microorganisms in the water and realize the separation of hydraulic residence time and sludge age, which makes the operation control more flexible and makes it possible to extend the sludge age, which is conducive to the growth and reproduction of nitrifying bacteria that proliferate slowly, and the denitrification efficiency is greatly improved. At the same time, because the system has a long sludge age, the amount of residual sludge generated is very small.

High-quality and stable effluent water quality

Due to the high efficiency of membrane separation, the separation effect is much better than the traditional sedimentation tank, and the treated water is extremely clear, with suspended matter and turbidity close to zero, bacteria and viruses are greatly removed, and the effluent quality is better than the water quality standard for domestic miscellaneous water issued by the Ministry of Construction (CJ25.1-89), which can be directly reused as non-potable municipal miscellaneous water.

At the same time, the membrane separation also makes the microorganisms completely intercepted in the bioreactor, so that the system can maintain a high concentration of microorganisms, which not only improves the overall efficiency of the reactor in removing pollutants and ensures good effluent quality but also makes the reactor very adaptable to various changes in the influent load (water quality and water quantity) and resistant to shock load so that it can obtain high-quality effluent water stably.

Easy to transform from the traditional process

The process can be used as a depth treatment unit of the traditional wastewater treatment process and has broad application prospects in areas such as the depth treatment of the effluent from secondary urban wastewater treatment plants (thus realizing the reuse of a large amount of urban wastewater).

Effective reduction of pollutant concentration

MBR, as a biochemical treatment process, can convert organic matter into carbon dioxide and water, nitrogen pollutants into nitrogen, and also reduce the conductivity of raw water, which makes the subsequent membrane treatment process load greatly reduced, extending the membrane life, increasing the water production rate, and reducing the concentration of the concentrated solution

Small footprint

Due to the high retention rate of the membrane system, it is possible to maintain a high sludge concentration in the reactor, usually 3-5 times that of the traditional activated sludge method. The high sludge concentration makes the reactor volume much smaller than that of the traditional process, and with the deep water oxygen supply form of the rate, the biochemical part covers a much smaller area than that of the traditional process.

The process has low residual sludge production, which reduces the sludge treatment cost.

The sludge load is very low, the nutrients in the reactor are relatively lacking, the microorganisms are in the endogenous respiratory zone, and the sludge yield is low, thus making the amount of residual sludge produced very small.

Convenient operation and management, easy-to-realize automatic control

MBR membrane process usually adopts DDC way control or PLC way control device. Automatic control, reduce manual labor, and convenient management.

MBR membrane disadvantages

High membrane cost, so the membrane-biological reactor infrastructure investment is higher than the traditional wastewater treatment process

The membrane module is the main component of the MBR treatment system, and it is also the part with the highest technical content and the largest value, and its cost occupies a large part of the overall equipment investment.

Membrane contamination can easily occur and affect the produced water

MBR is usually carried out at constant flux, and in order to run continuously, MBR must not exceed the limit flux, beyond which membrane contamination will occur, and then the excess water will not be able to pass through the membrane pore size, and the water production rate will be reduced.

High energy consumption

First of all, the MBR mud-water separation process must maintain a certain membrane drive pressure, followed by a very high concentration of MLSS in the MBR pool, to maintain sufficient oxygen transfer rate, we must increase the aeration intensity, and in order to increase the membrane flux, reduce membrane pollution, we must increase the flow rate, scouring the membrane surface, resulting in the energy consumption of MBR than the traditional biological treatment process is high.

Many influencing factors

Since the improvement of membrane flux and the extension of membrane life will significantly reduce the operating cost of MBR, the membrane flux should be as large as possible under the premise of ensuring the effluent water quality, which can reduce the area of membrane usage and lower the infrastructure cost and operating cost.

Therefore, controlling membrane contamination and maintaining high membrane flux is an important part of MBR research. The membrane flux is closely related to the membrane material, operation method, hydraulic conditions, and other factors.

Membrane bioreactor (MBR) is an emerging technology combining membrane treatment technology and the traditional bioactive sludge method, which is mainly used for domestic wastewater treatment, water treatment, and treatment of industrial wastewater containing high organic matter and toxic and harmful substances, and has a broad development prospect.

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024