Nanofiltration membranes: capable of retaining nanoscale (0.001 micron) substances. The operating range of nanofiltration membrane is between ultrafiltration and reverse osmosis, the molecular weight of the retained organic matter is about 200-800, the ability to retain dissolved salts is between 20%-98%, the removal rate of soluble monovalent ions is lower than that of high-valent ions, nanofiltration is generally used for the removal of organics and pigments in surface water, the hardness of groundwater and radium, and partially removes dissolved salts, which is useful in the production of food and medicine. It is also useful in the extraction and concentration of substances in food and pharmaceutical production. The operating pressure of nanofiltration membrane is generally 3.5-30 bar.

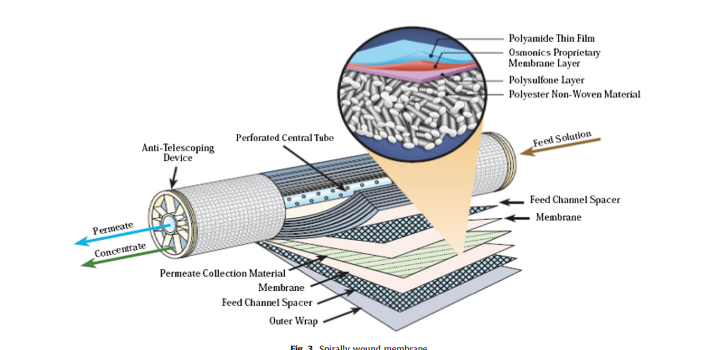

Reverse osmosis (RO) membranes are the finest membrane separation products, which can effectively retain all dissolved salts and organic matter with molecular weights greater than 100, while allowing water molecules to pass through. Reverse osmosis membrane is widely used in the desalination of seawater and brackish water, boiler make-up water, industrial pure water and electronic high-purity water preparation, drinking water production, wastewater treatment and special separation processes.

Ultrafiltration membrane: It can retain large molecules and proteins between 1-20nm. Ultrafiltration membrane allows small molecules and dissolved solids (inorganic salts), etc. to pass through, and at the same time will intercept colloids, proteins, microorganisms and macromolecules of organic matter, ultrafiltration membrane operating pressure is generally 1-5bar.

Ultrafiltration membrane and the difference between nanofiltration membrane and reverse osmosis membrane:

Ultrafiltration membrane: Ultrafiltration membrane is a pressurized membrane separation technology, that is, under a certain pressure, so that small molecules of solutes and solvents through a certain pore size of the special film, while the large molecules of solutes can not pass through the membrane, stay on the side of the membrane, so that the large molecules of substances have been partially purified.

Nanofiltration: Nanofiltration, between ultrafiltration and reverse osmosis. Now it is mainly used as water plant or industrial desalination. Desalination rate of more than 90 percent. Reverse osmosis desalination rate of more than 99% But if the water quality requirements are not particularly high, the use of nanofiltration can save a lot of cost.

Reverse osmosis: reverse osmosis, is the use of pressure gauge difference as the driving force of the membrane separation and filtration technology, has been widely used in scientific research, medicine, food, beverage, seawater desalination and other fields. It is used for the preparation of space water, pure water, distilled water, etc.; water used for liquor manufacturing and degradation; pre-preparation of water used in medicine, electronics, etc.; concentration, separation, purification and preparation of water distribution for chemical process; desalination of boiler make-up water; desalination of seawater, brackish water; water used for papermaking, electroplating, printing and dyeing, etc., as well as wastewater treatment.

Comparison of the advantages and disadvantages of reverse osmosis membrane and ultrafiltration membrane

Reverse osmosis membrane pore size is only ultrafiltration membrane 1/100 proportion of the size of the membrane, so reverse osmosis water treatment equipment can effectively remove heavy metals, pesticides, trichloromethane and other chemical pollutants in the water quality, ultrafiltration water purifier is unable to do this. Ultrafiltration water purifier can remove the particles of pollutants and bacteria, reverse osmosis all remove.

Reverse osmosis and ultrafiltration core components are membrane elements, the main difference between a total of two points:

- Water quality and health department testing standards are different, to give you an example to illustrate, the water bacterial indicators, ultrafiltration in accordance with the “general water processor”, the total number of colonies of 100 / ml; and reverse osmosis water treatment equipment for the 20 / ml, the requirements of a more stringent, of course, the reverse osmosis water treatment equipment, water quality is much better than the ultra-filtration. Also much better than ultrafiltration.

- Reverse osmosis water treatment equipment is a quality water supply, pure water supply for drinking, concentrated water used for washing; and ultrafiltration is generally used for washing water; when the tap water quality is relatively high quality can also be used as drinking water ultrapure water equipment.

Advantages of ultrafiltration: generally do not use pumps, no power consumption, no electrical safety issues; fewer joints, low water pressure, failure rate and the probability of leakage is relatively low; simple structure, inexpensive; easy to operate, low cost, do not need to add any chemical reagents, especially ultrafiltration technology, the experimental conditions of the mild, compared with the evaporation, freeze-drying, there is no phase change, and does not cause temperature, pH changes, and thus can prevent the denaturation, inactivation of biological macromolecules. The denaturation, inactivation and autolysis of biomolecules can be prevented. In the preparation technology of biomolecules, ultrafiltration is mainly used for desalination, dehydration and concentration of biomolecules.

Advantages of reverse osmosis water treatment equipment: water quality safety, can effectively remove all kinds of harmful impurities in the water quality; better effect for water supply special events; better taste of the water; can effectively reduce the hardness of water, boiling water containers are not easy to scale.

Application of different membranes in water treatment

Nanofiltration membranes are used in the preparation and deep purification of drinking water, in wastewater treatment: domestic sewage, textile, printing and dyeing wastewater, tannery wastewater, electroplating wastewater, paper wastewater.

Forward osmosis (FO) applications: seawater desalination, industrial wastewater treatment, waste leachate treatment

Reverse osmosis membrane: conventional water purification applications, municipal wastewater applications, heavy metal wastewater treatment applications Oil-containing wastewater applications.

Water treatment membrane technology working principle and process flow:

Utilizing membrane technology as the core filtration material, supplemented by pretreatment or other equipment, to achieve the purpose of purification.

Two-stage reverse osmosis pure water process flow:

Raw water → quartz sand filter → activated carbon filter → security filter → multi-stage pump → first reverse osmosis membrane (concentrated water recovery) → multi-stage pump → second reverse osmosis membrane (concentrated water recovery) → pure water

One-stage reverse osmosis pure water process:

raw water → quartz sand filter → activated carbon filter → security filter → multi-stage pump → one-stage reverse osmosis membrane (concentrated water recovery) → pure water

Mineral water, spring water, water purification process:

Raw water → quartz sand filter → activated carbon filter → security filter → ultrafiltration membrane → mineral water, spring water

Ultra-pure water, deionized water process flow:

Raw water→quartz sand filter→activated carbon filter→security filter→multistage pump→first-stage reverse osmosis membrane (concentrated water recovery) (or second-stage reverse osmosis process) →first-stage mixed-bed equipment→second-stage mixed-bed equipment→ultra-pure water