October 18, 2022

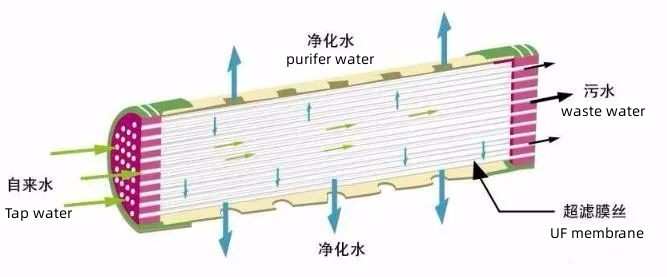

As a membrane separation technology, ultrafiltration (UF) is one of the hot spots of research in the world of water treatment.

Ultrafiltration (UF) is superior to the filtration ability in conventional water treatment technology for removing micron-level particles in water, and also has the ability to remove nanometer-level particles that filtration does not have, which meets the requirements of improving drinking water quality and the requirements of industrial water pre-treatment.

At present, in the water industry market, ultrafiltration (UF) technology has been widely used in industrial wastewater treatment fields such as electric power, steel, and chemical industry.

The increasing scale of urban water reuse projects and the introduction of new drinking water standards are putting forward higher requirements for urban and rural drinking water treatment, which also opens up wide market space for ultrafiltration(UF) membrane technology.

Advantages of ultrafiltration(UF) membrane technology

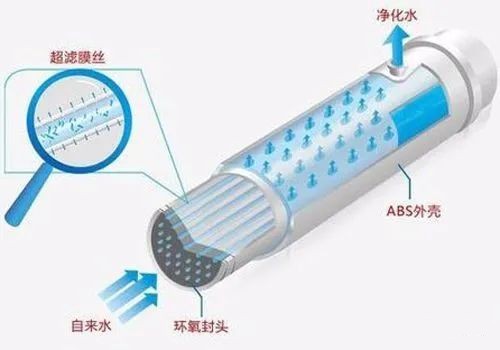

A high recovery rate of the system, and excellent quality of the product obtained, can achieve high-efficiency separation and purification of materials and high concentration.

No phase change in the process, no adverse effect on the composition of the material, and the separation and purification process are always at room temperature, which is suitable for the treatment of heat-sensitive substances, completely avoiding the disadvantage of high temperature on the destruction of biologically active substances, and effectively retaining the living substances and nutrients in the original material system.

The system has low energy consumption, a short production cycle, and low operating costs compared with traditional process equipment, which can effectively reduce production costs and improve the economic efficiency of enterprises.

Advanced system process design, high degree of integration, compact structure, small footprint, easy operation and maintenance, low labor intensity of workers.

The system is made of sanitary pipe and valve, the site is clean and hygienic, meeting the requirements of GMP or FDA production standards.

The filtration process is carried out at room temperature, with mild conditions and no component destruction, so it is especially suitable for the separation, classification, concentration, and enrichment of heat-sensitive substances, such as drugs, enzymes, fruit juices, etc.

The filtration process does not undergo a phase change, has no heating, low energy consumption, no need to add chemical reagents, and no pollution, and is an energy-saving and environmentally friendly separation technology.

ultrafiltration (UF) technology has high separation efficiency and is very effective for the recovery of trace components in dilute solutions and the concentration of low-concentration solutions.

The ultrafiltration method also has certain limitations, it cannot directly obtain dry powder preparations. For protein solutions, generally, only 10 to 50% concentrations can be obtained.

The disadvantages of ultrafiltration membrane technology

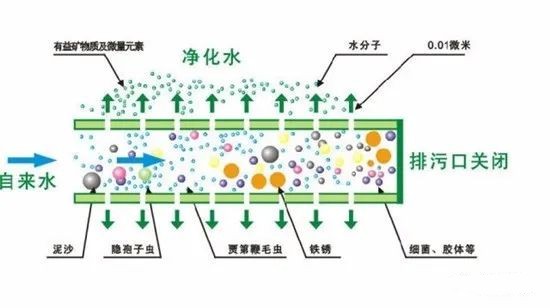

(1) Ultrafiltration (UF) membrane cannot effectively remove dissolved organic pollutants, such as oxygen consumption, UV254, ammonia nitrogen, etc.

(2) The membrane filament breakage may occur during use, resulting in the raw water entering the produced water side directly through the broken membrane filament, affecting the effluent water quality.

(3) The membrane system is greatly affected by temperature. When the water temperature is high, the viscosity of water is larger, if the flux remains the same, it will cause TMP and membrane resistance coefficient to rise more significantly, which will trigger frequent backwash membrane flux to drop rapidly. When the temperature is very low, the water in the membrane shell may freeze due to low temperature and cause harm to the membrane filament.

(4) There is a serious membrane contamination problem when ultrafiltration (UF) membrane filtration is used directly, membrane contamination is mainly caused by lower inorganic salts, colloids and dissolved organic matter and sludge, membrane biodegradation products, etc.

(5) Poor effect of removing chemical pollutants in water; poor effect on water supply special events; slightly worse mouth feeling of water discharge; cannot reduce the hardness of the water.

Ultrafiltration(UF) application development

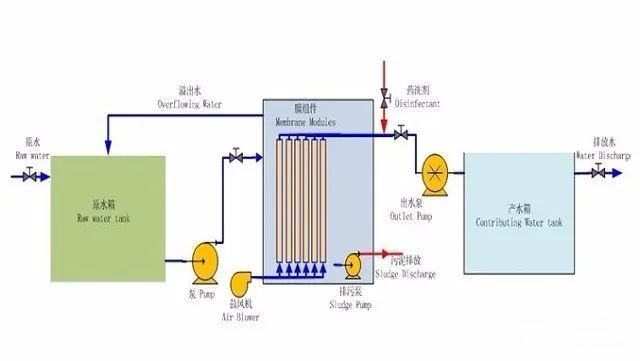

The application of ultrafiltration(UF) membrane technology in the three fields of MBR, desalination pretreatment, and wastewater reuse are basically equally divided, each occupying about 20% of the market share.

However, at present in China, ultrafiltration membrane occupies a larger market share in the field of wastewater reuse, and in the water industry market, ultrafiltration (UF) technology has been more applied in industrial wastewater treatment fields such as electric power, steel, and chemical industry.

With economic and social development, there will be more and more large-scale wastewater treatment projects, opening up broad market space for ultrafiltration membrane technology. In recent years, various countries around the world have started to enter a period of serious water shortage, and water quality pollution has gradually become the biggest obstacle to safe water supply in cities of various countries.

Urban domestic sewage treatment and water reuse will become one the most effective ways to solve the future urban water crisis. Therefore, ultrafiltration membranes will have a broad market space in the future municipal wastewater treatment market.

With the development of membrane technology and the gradual reduction of membrane price, replacing traditional deep treatment units with ultrafiltration technology to a certain extent has gradually become a reality.

However, there is still a need to invest more human and financial resources in the independent research and development of membrane components and membrane systems.

Through the development of new processes to solve the ultrafiltration membrane in the operation of the need for more stringent raw water quality requirements, membrane pollution caused by the membrane life-shortening and other problems, increase the membrane varieties, improve the membrane technology application of process design, system set capacity, improve the degree of industrialization, strict control of process parameters.

In this way, the ultrafiltration membrane technology can be more widely developed in the process of drinking water treatment, so that the quality of the effluent from drinking water treatment can be further improved.

Detailed Operating Instructions for Automatic Dosing Systems

December 26, 2024

Characteristics and Applications of Precision Filters

December 19, 2024