In order to make the RO reverse osmosis plant safe and reliable, and to facilitate the monitoring of the operation process, the necessary meters and control equipment should be installed.

Generally, the meters to be installed are temperature meter, pressure meter, flow meter, pH meter, conductivity meter, chlorine meter, redox potential meter, etc. The installed locations and their roles are described below.

Temperature Meter

Feed water temperature table, because the water production is related to the temperature, so need to check in order to find out the “standardized” after the water production. Large equipment should be recorded, in addition, the temperature exceeds 45 degrees Celsius will damage the membrane elements, so the raw water heater system should be equipped with over-limit alarm, over-temperature water automatic discharge and shutdown RO protection.

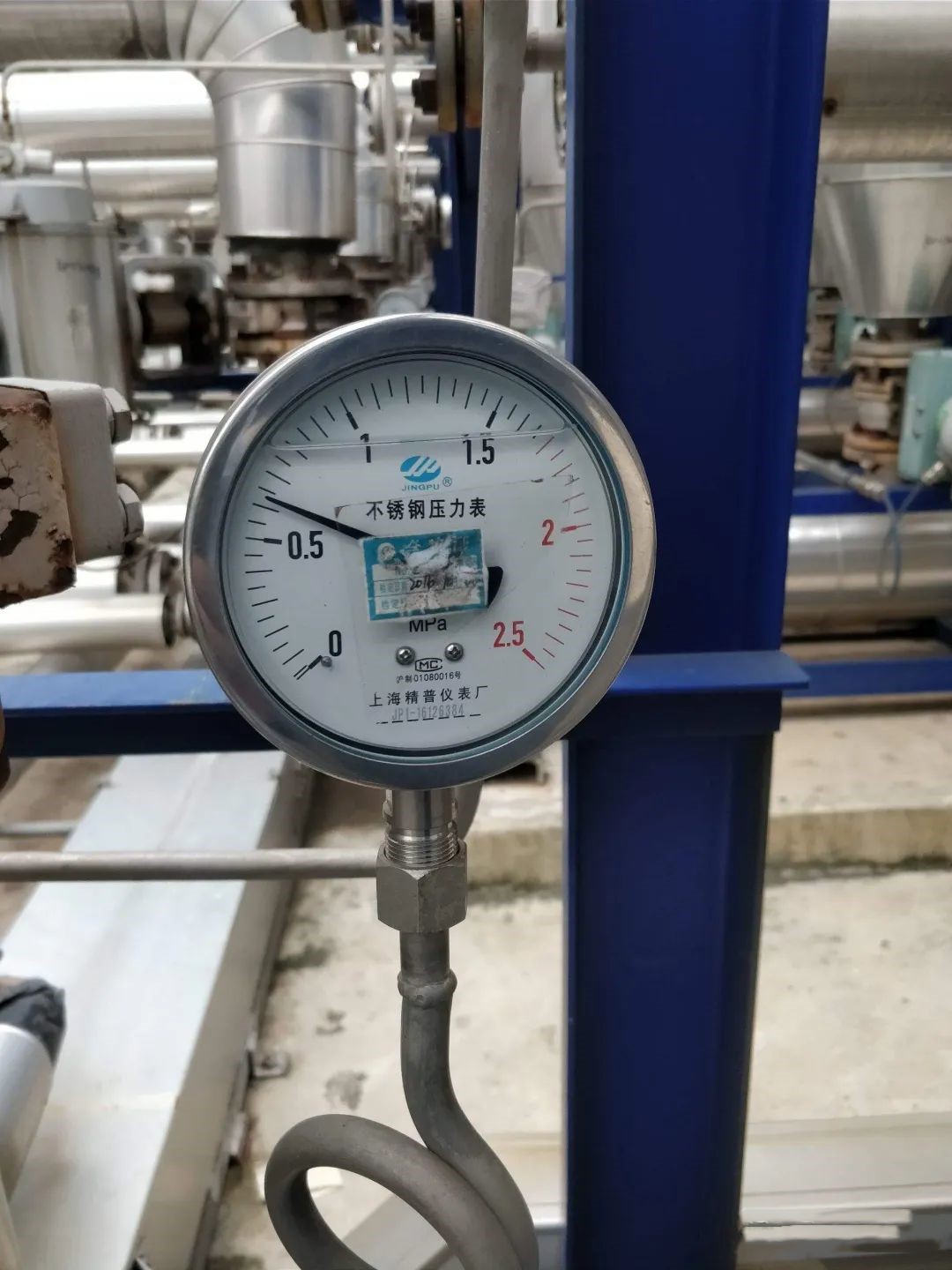

Pressure Gauges

The feed water pressure gauge, the first RO discharge pressure gauge, and the drainage pressure gauge are used to calculate the pressure drop in each section and to “standardize” the water yield and salt transmission rate. The salt transmission rate and water yield are used for analysis of RO performance problems. 5 micron filters are equipped with inlet and outlet pressure gauges, and the cartridge needs to be replaced when the pressure drop reaches a certain value. The feed pump import and export pressure gauge is used to detect the feed pump import and export pressure, and the import and export pressure switch is used to alarm and stop the pump when the import pressure is low, and to alarm and stop the pump when the export pressure is high.

Flow Meter

Product water flow meter in the operation of the detection of water production, each section should be installed separately, in order to “standardize” RO performance data. Product water flow rate should be indicated, accumulated and recorded. Concentrated water drainage flow meter in operation to detect the amount of drainage, should be indicated, total and recorded. From the product flow rate and drainage flow rate of each section, the feed water, recovery rate and overall RO system recovery rate of each section can be calculated. The feed water flow meter is mainly used for automatic adjustment of RO dosing (acid addition, scale inhibitor addition and sodium bisulfite addition are often shared by two sets of RO), and it should give signals for proportional adjustment in addition to indication and accumulation.

Conductivity Meter

Feed water conductivity meter, product water conductivity indication, record water conductivity, alarm can be set, from the feed water conductivity and product water conductivity can estimate the desalination rate of RO.

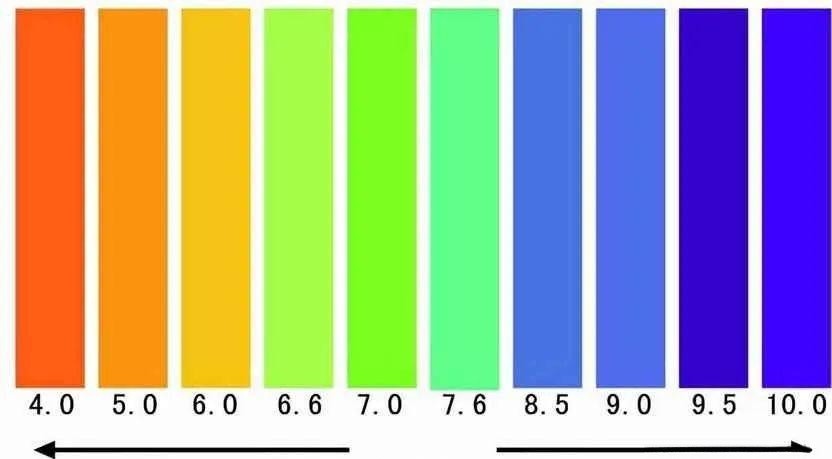

PH Meter

When the feed water needs to add acid to prevent CaCO3 scale, the acid feed water needs to be equipped with pH meter, in the use of cellulose acetate membrane type, not only to prevent CaCO3 scale generation, but also more importantly to maintain the best pH value. The pH value of cellulose acetate membrane is 5.7. In addition to indicating, recording and setting over-limit alarm, it can also automatically control the discharge of unqualified feed water and stop the operation of RO, and it can also cooperate with flow meter to adjust the proportional integral of acid addition system.

Nitrogen Meter

Using cellulose acetate membrane element RO feed water must contain 0.1 ~ 0.5mg / L residual chlorine, the maximum allowable nitrogen content of 1mg / L, so the feed water must be installed with nitrogen table to indicate, record and exceed the limit alarm. The liquid tank should be equipped with a level switch, low level alarm, acid addition can be proportionally adjusted or proportional integral adjustment, scale inhibitor and other proportional adjustment, and interlock between the dosing pump and feed pump.

Redox Potential Table

By adding sodium bisulfite to eliminate the residual chlorine feed water should be equipped with redox potential table, there should be instructions, records, over the limit alarm.