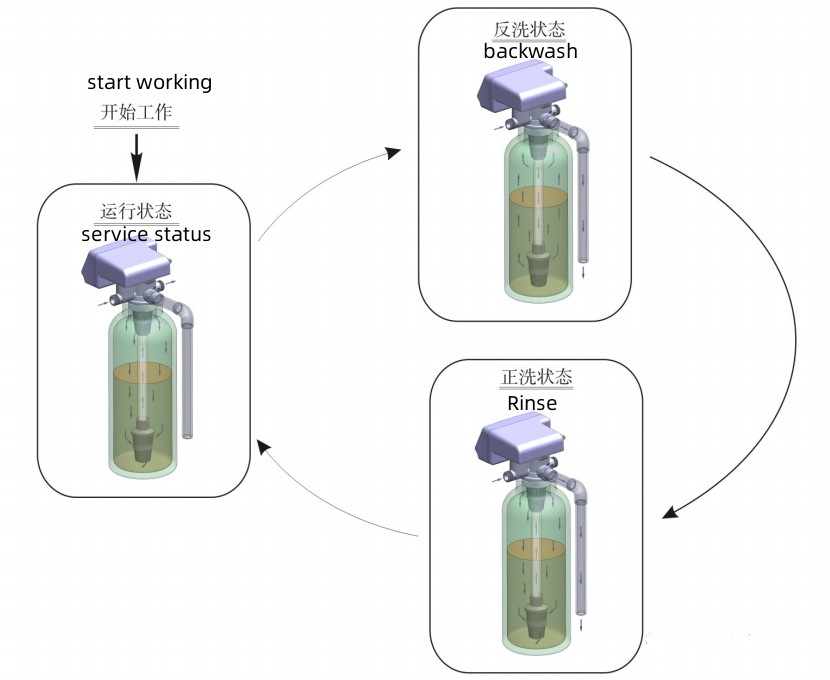

The operation of the general water filtration system is: the operation of the water flow from the top down through the filter layer to remove the suspended matter in the water;

when the head loss of the water flow filter layer (also known as pressure drop) reaches the allowable value or the turbidity of the effluent begins to exceed the allowable value, in order to restore its interception capacity, to use fast water to backwash from the bottom up, in order to remove the slag retained in the operation of the filter layer and the powder generated by the broken filter media;

after backwashing , the water is washed from top to bottom until the turbidity of the water is qualified, and then put into the next cycle of filtration operation.

Therefore, the filtration operation is in a cyclic cycle, consisting of three steps of running filtration, backwashing and rinse.

The actual running time between the two backwashes is called the filtration cycle.

The operating effect of filtration is usually evaluated by two aspects: one is the water quality, often expressed in terms of turbidity;

the other is the dirt interception capacity of the filter layer, also known as sludge capacity, which refers to the quality of sludge that can be retained per unit volume of filter media throughout the filtration cycle under the condition that the water quality of the filter equipment is qualified.

There are many factors affecting the filtration effect, mainly the filtration speed, backwashing and uniformity of water flow, etc., which are described as follows

Filtration Speed

The filtration speed (v) during filtration can be calculated by the following equation:

v = Q/S m/h

Where:

Q – the output of the filter, m3/h;

S – filter cross-sectional area of the filter, m2.

As can be seen from the formula, the filtration speed here does not refer to the actual speed of water through the pores between the filter media, but assumes that the filter media does not occupy the space when the water through the filter pool speed, is a relative data to indicate the speed of water flow in the filter pool.

The filtration process is a gradual saturation of the filter layer from top to bottom by the suspended matter in the water. Therefore, the size of the filtration speed not only affects the transport of suspended matter to the surface of the filter media, but also has a hydraulic shear effect on the suspended matter that has been retained or adsorbed by the filter media.

If the filtration speed is too fast, the hydraulic shear effect is greater than the adsorption effect, it will make the turbidity of the effluent rise, head loss increases, shorten the filtration cycle.

If the filtration speed is too slow, it means that the filter unit area of the output force is reduced, such as to achieve a certain output force, you have to increase the filtration area, so that the equipment becomes large, and increase investment.

Therefore, the optimal filtration speed of the filter should be determined by debugging according to the characteristics of the filter media and the water quality conditions of the incoming and outgoing water.

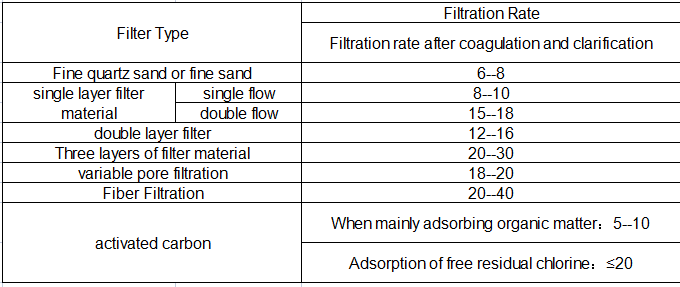

The maximum allowable filtration speed depends mainly on the particle size of the filter media. The smaller the particle size is, the smaller the allowable filtration speed is. The operating filtration speed of common filters can be referred to the following table.

BackWashing

The good or bad filtration effect during operation can be monitored by measuring the turbidity of the effluent. However, this indicator does not indicate the progress of the filter layer interception,

because in the filtration operation, the change of the turbidity of the water is not strong, when the operation to the turbidity of the water significantly increased, the filter layer has often been seriously polluted,

if then backwashing, it will be difficult to make the filter layer flush clean. Therefore, in operation to determine whether the filter needs to backwash the actual indicators of supervision is not turbidity, but the head loss of the water flow filter layer, this is because the change of head loss in filtration operation is more obvious, and the measurement of pressure is also relatively simple.

When the filter runs until the head loss (i.e., differential pressure) reaches a certain value, it should stop running and backwash.

The reason why the filter cannot be run until the differential pressure is too large before backwashing is that when the head loss is large, the inlet pressure must be increased to achieve a certain output force, which will easily cause the filter layer to rupture and a large amount of water will pass through the cracks of the filter membrane, destroying the filtration effect and making the output water quality deteriorate quickly.

In actual operation, the differential pressure of the filter should be controlled at a much lower pressure than that caused by the rupture of the filter layer. In this way, the filter layer can be prevented from being polluted too much, and the backwash is not easy to be thorough, and it causes bad consequences such as clumping of filter media.

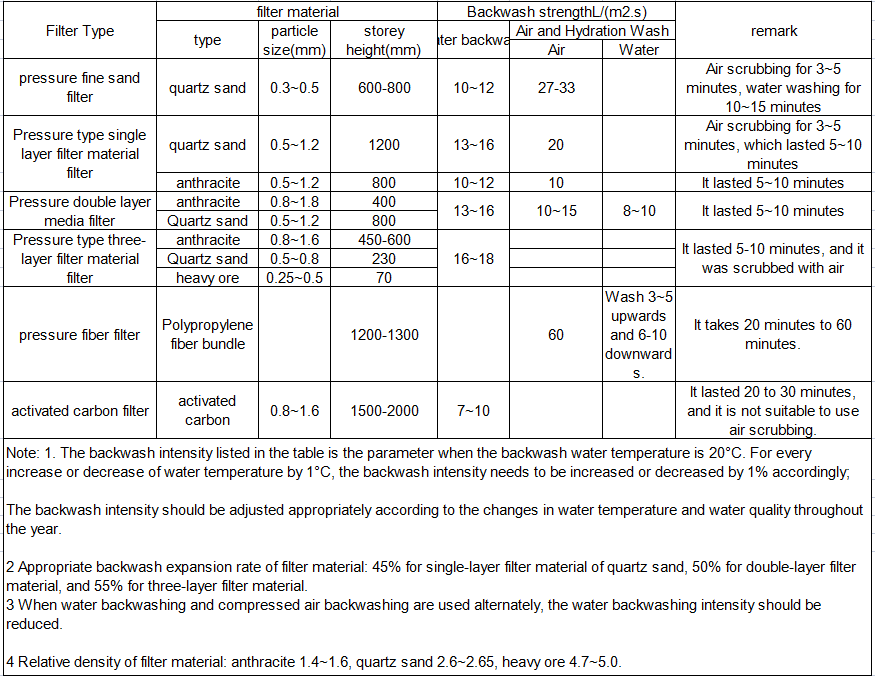

The size of the water velocity during backwashing can be expressed as “backwashing intensity”, whose unit is L/(m2-s), indicating the backwashing water volume (liters) flowing through each square meter of filtration section per second.

Backwashing intensity should be appropriate, both enough to make the filter layer fully loose, so that particles can collide and rub each other, while flushing away the mud slag and tiny filter debris, but not so much as to take away the normal filter particles.

In various specific operating conditions, the most suitable backwashing strength should be obtained through experiments.

It is difficult to estimate because it is related to many factors such as the particle size and density of the filter media particles, and the water temperature.

Generally speaking, the backwashing strength of quartz sand is (13 ~ 16) L/(m2-s), the water washing time is 10min~15min, and the air scrubbing time is 3min~5min; while the backwashing strength of anthracite coal is (10~12) L/(m2-s),

the backwashing time is 5min~10min due to its small density; the backwashing strength of activated carbon is (7~10) L/(m2-s)

The backwashing intensity of activated carbon is (7-10) L/(m2-s), and the backwashing time is 20min~30min.

When backwashing, due to the rapid upward flow of water, the filter media particles are loosened and the filter layer is swollen.

The ratio of the increased height after the expansion of the filter layer and the height before the expansion is called the expansion rate of the filter layer, which is used to measure the backwashing strength of an indicator.

The general expansion rate of the filter layer should be 25% to 50%.

In order to improve the backwashing effect and reduce the backwashing water, some filtration equipment is also equipped with compressed air pipeline, so that the filter media stirred up with compressed air.

Uniformity of water flow

In the process of filtration or backwashing, the water filtration system requires uniform water flow distribution along each part of the filter layer cross-section, otherwise, it will affect its maximum effectiveness.

However, the water entering from the main inlet pipe, when passing through each part of the filter layer, there is always a difference in pressure loss along the way because of the distance travelled, so it is not possible to achieve the absolute average water flow in each part.

In the water filtration system, the greatest impact on the uniformity of water flow is the water distribution system (or drainage system).

The water distribution system is a device placed under the filter layer to collect the filtered water when filtering and to feed the backwash water when backwashing.

In order to make the water flow evenly, the design of the water distribution system must be reasonable.