Structure and material

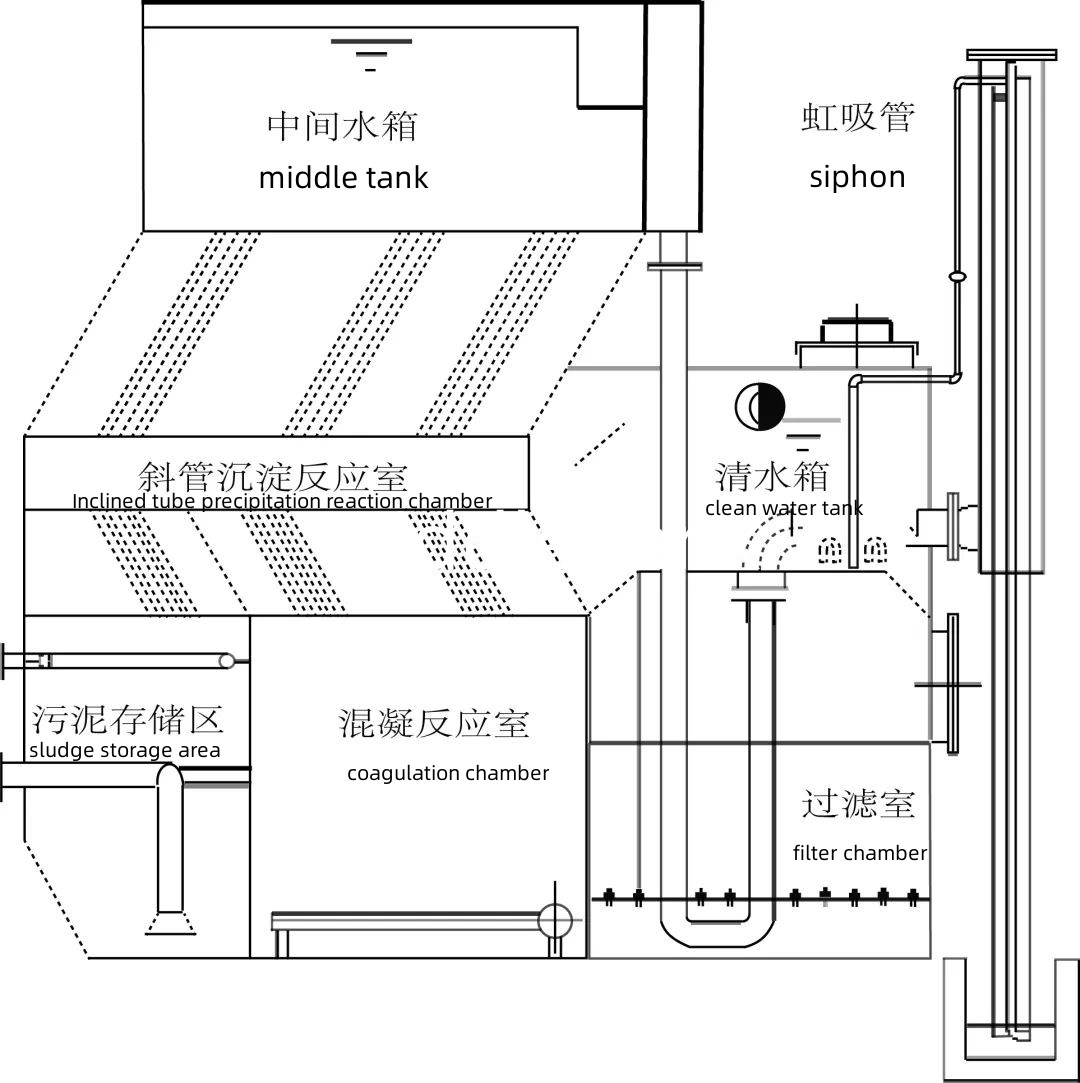

1.package sewage treatment plant

The package sewage treatment plant contains all the main nuclear attachments and materials (water purifier main body, inclined plate, filter media, mud discharge system, water discharge system, inspection channel, inlet and outlet valves, etc.).

- Raw water tube filter

Raw water pipe filter 2 sets, respectively installed in the two water purifiers on the inlet branch pipe.

- Tube static mixer

Static mixer has simple structure and small footprint. It is made of glass steel, which is easy to process, durable and corrosion resistant. It adopts advanced foreign technology, with good mixing effect and small head loss; it is connected in series in the conveying pipeline, which does not occupy another area and saves engineering land area; there are no moving parts, and the components only have hydraulic wear and tear, which has a long life and requires no maintenance. Mixer diameter according to the economic flow rate to choose, generally calculated by 0.9-1.2m / s; pipe diameter greater than 500mm maximum flow rate of up to 1.5m / s calculation. When available, the pipe diameter will be enlarged by 50-100mm, in order to reduce head loss. Mixer section number of basic combinations of three sections to consider, head loss of about 0.4-0.8 m. Can also increase or decrease the number of sections according to the case of mixed media. The water pressure in the mixer tube is considered by 0.1kg/c㎡, and the equipment can also be processed according to the actual pressure.

- Dosing system

Dosing system uses metering pump or flow meter to add coagulant and coagulant. It is used for alkaline aluminum chloride dosing and has a self-flushing device. The dissolution tank is mechanically stirred, and the storage volume is available for at least 18h, including valves and electrical control equipment. Each set of dosing device is individually assembled on its own combination frame, so that the dosing pump, dissolution tank, buffer, filter, pipeline, valve, etc. form an independent whole. The main materials of dosing equipment are made of steel compound glass steel and other materials. Equipment using electric arc (argon arc welding) welding, in the case of checking the quality of the weld seam no problem; inside and outside the equipment de-slag polishing; water pressure test without leakage conditions; in the factory by the appearance inspection, water pressure test, site acceptance test and the necessary corrosion resistance test, and can be used in a certain state of overload good.

- Disinfection system

It adopts metering pump for dosing, considers dosing before and after, uses bleaching essence (or bleaching powder) for dosing, and has self-rinsing device. The dissolution tank is mechanically stirred, and the storage volume is available for at least 18h, including valves and electrical control equipment.

- Backwashing system

The backwashing system includes a full set of equipment such as pumps, air pumps, valves and electrical control equipment. It adopts double-ring multi-spout rotary flushing system, which has good flushing effect and low water consumption.