Gas station project- RO Plant- South America

Output Capacity: 1000LPH

Feedwater flow: 2000LPH

Recovery rate: 40-55%

Reject salt: 98-99%

Application: purify water for life use

Source water: underground water

TDS of source water: 1500mg/L

Pure water conductivity: ≤80mg/L

Voltage: 220v, 50HZ 1P

In Europe, America, some countries, large factories, gas stations, highway service areas and other places where people are more concentrated or more people flow, need to use a large number of drinking water.

In these places, generally in remote areas, far from the city, the tap water is difficult to deliver, mainly using groundwater for treatment as drinking water, and groundwater quality situation is more complex, simple treatment is often difficult to achieve drinking water requirements, the need for reverse osmosis treatment.

ROAGUA built a reverse osmosis plant for a gas station to provide drinking water for staff and customers passing by the gas station.

The raw water was groundwater, whose average water quality measurement results: TDS value was 1500mg/L, hardness was 300ppm (6mmol/L), iron ion content was 4-5mg/L, manganese ion content was 0-2mg/L, chloride content was 450mg/L, which belonged to brackish water with high salt content and high hardness. Requirements for clarification, TDS value ≤ 80mg / L, hardness ≤ 30ppm (0.6mmol / L), chloride content ≤ 30mg / L, water production flow of 0.5m3 / h of drinking water.

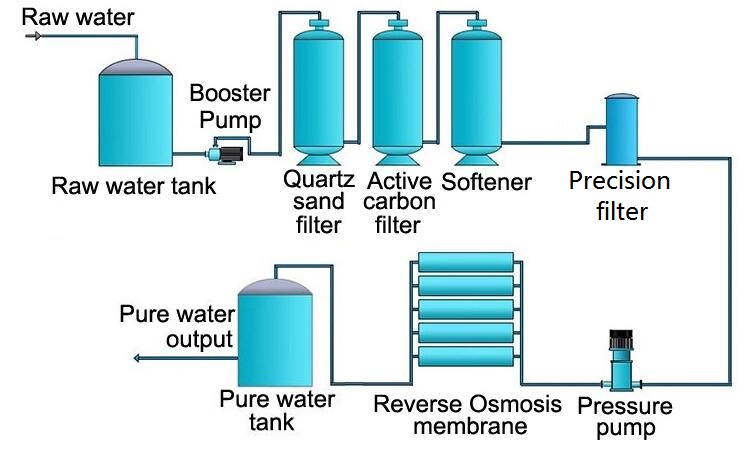

For this reason, the design uses RO plants to remove salt and reduce hardness.

Considering that the iron and manganese content of groundwater exceeds the standard and is easy to contaminate the RO membrane, the raw water is pretreated with chlorine and sodium hydroxide and then enters the reverse osmosis plant through the iron and manganese removal device, followed by activated carbon filtration and resin softening.

Adopt Runxin automatic filter valve, configure iron and manganese removal and activated carbon filter; a set of Runxin automatic water softening valve, matching resin tank with diameter 0.4m and height 1.65m, form pretreatment device

The process flow chart is: well water → pump → adds chlorine and sodium hydroxide → removes iron and manganese filtration → activated carbon filtration → softening → RO host → drinking water tank → booster pump → disinfection → drinking water point.

The reverse osmosis plant has been installed and used since early 2017, with stable system operation, qualified water production and good automation control.